Why do garment interlinings blister?

1. Fabric and interlining suitability issues

(1) Differences in fabric characteristics: the fiber structure and properties of different fabrics are different, such as natural fiber fabrics (cotton, linen, silk, wool) and chemical fiber fabrics (polyester, nylon, etc.) in the hygroscopicity, thermal stability and other aspects of the existence of significant differences. If the interlining and fabric in these characteristics do not match, in the subsequent processing or wearing process, due to changes in environmental factors, it is easy to lead to the two contraction or expansion degree is not consistent, thus triggering the interlining blistering. For example, cotton fabrics are highly hygroscopic, there will be a large contraction in water, if the matching interlining fabrics with poor hygroscopicity and high dimensional stability, the phenomenon of blistering may occur after washing.

(2) fabric thickness and texture: thinner or loose texture of the fabric, the lining of the higher fit requirements. If the choice of interlining cloth is too thick or too hard, in the bonding process, it is difficult to combine with the fabric uniformly tight, will form a gap between the two, with the passage of time or by the action of external forces, the air into the gap leading to blistering. Such as light silk fabrics, if the use of thicker non-woven lining, it is easy to appear such problems.High quality interlining fabrics from China

2. Bonding process problems

(1) Improper temperature control: bonding temperature is the key factor affecting the effect of bonding of interlining and fabric. Temperature is too low, the hot melt adhesive can not be fully melted, can not form a good bonding effect, resulting in interlining and fabric combination is not firm, easy to blister; temperature is too high, the hot melt adhesive will be excessive melting or even carbonization, not only damage the structure of the interlining and fabric, but also may make the adhesive layer is not uniform distribution, will also trigger blistering. Different combinations of interlining fabrics and fabrics, have their appropriate bonding temperature range, such as ordinary polyester fabrics and hot melt interlining bonding temperature is generally in the 120 - 150 ℃, if beyond this range, it is easy to have problems.

(2) uneven pressure: in the bonding process, if the pressure applied is not uniform, will make the lining and fabrics of various parts of the bonding degree is not consistent. Pressure is not enough area, the bonding effect is poor, easy to bubble; pressure is too large area, may damage the fabric and lining, also affect the bonding quality. For example, the use of flatbed bonding machine, if the equipment pressure regulator failure, it will lead to uneven pressure distribution.

(3) Inaccurate control of time: if the bonding time is too short, the hot melt adhesive cannot fully diffuse and penetrate into the fabric fibers to form a strong bond; if the bonding time is too long, it will overheat the fabrics and interlinings, which will affect their performance and increase the risk of blistering. Generally speaking, the bonding time between 10 - 30 seconds is more common, but specific according to the fabric and interlining material, thickness and other factors to adjust.shenghong interlining factory china

3. Interlining quality problems

(1) Poor quality of hot melt adhesive: hot melt adhesive is the key component of the interlining fabric to achieve bonding with the fabric, and its quality directly affects the bonding effect. Low-quality hot melt adhesive may have unstable melting point, insufficient viscosity, poor aging resistance and other problems. For example, the melting point is not stable hot melt adhesive in the set bonding temperature, may not be able to melt normally, resulting in bonding failure; viscosity is not enough to make the interlining fabrics and fabrics close to the close, easy to blistering phenomenon; aging-resistant performance of the hot melt adhesive, in the clothing wearing and washing process, with the passage of time, the viscosity is gradually reduced, but also triggered by interlining fabrics blistering.

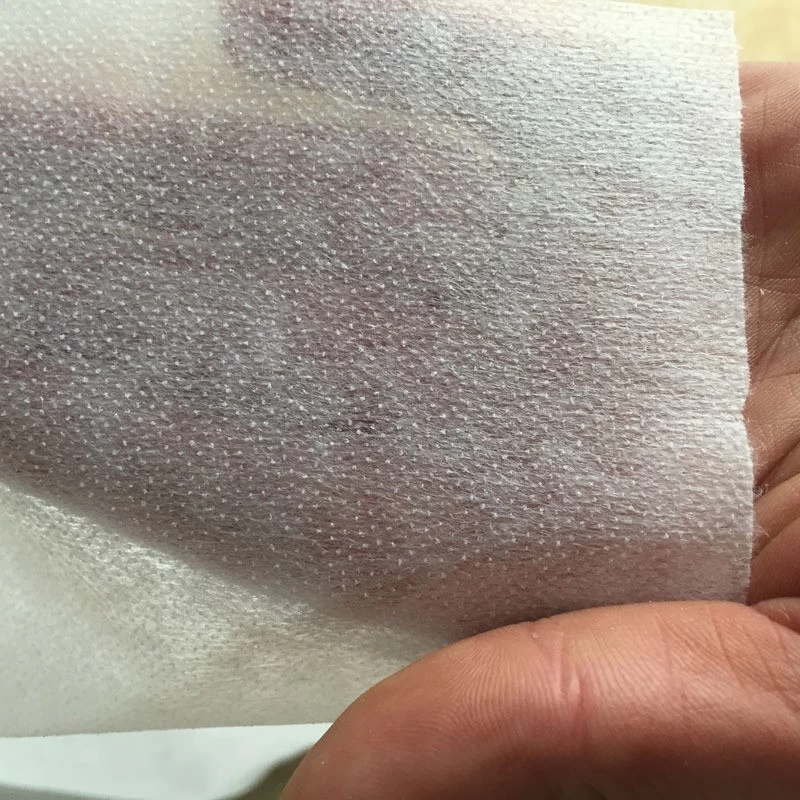

(2) Interlining base cloth problem: the quality of the base cloth of the interlining is equally important. If the fiber strength of the base cloth is low, poor uniformity, in the processing and use of the process, it is easy to deformation, affecting the lining and fabric fit. For example, the low strength of the base cloth fiber, when subjected to certain external forces, easy to break, resulting in partial loosening of the interlining, which in turn triggered blistering; poor uniformity of the base cloth, will make the hot melt adhesive coating on the base cloth is not uniform, affecting the bonding effect.

4. Storage and use of environmental issues

(1) The effect of humidity: too high humidity environment will make the lining and fabric moisture absorption, resulting in size changes. Especially for the more moisture-absorbent natural fiber fabrics and interlining fabrics, moisture absorption and expansion, and contraction in the drying process, this repeated dimensional changes are prone to make the interlining fabrics and the bond between the fabrics to reduce the bonding force, thereby triggering blistering. For example, in the humid rainy season in the south, if the humidity of the garment production workshop or warehouse is not properly controlled, it is easy to appear such problems.

(2) Temperature fluctuations: Drastic fluctuations in temperature will affect the performance of hot melt adhesive. In a high temperature environment, the hot melt adhesive may soften or even partially melt, resulting in a decrease in the adhesive strength between the interlining and the fabric; in a low temperature environment, the hot melt adhesive may become brittle and lose part of its stickiness. When garments are worn or stored in different temperature environments, this temperature change can lead to blistering of the interlining. For example, when garments are worn in winter, a large change in temperature from warm indoors to cold outdoors may cause blistering of the interlining.