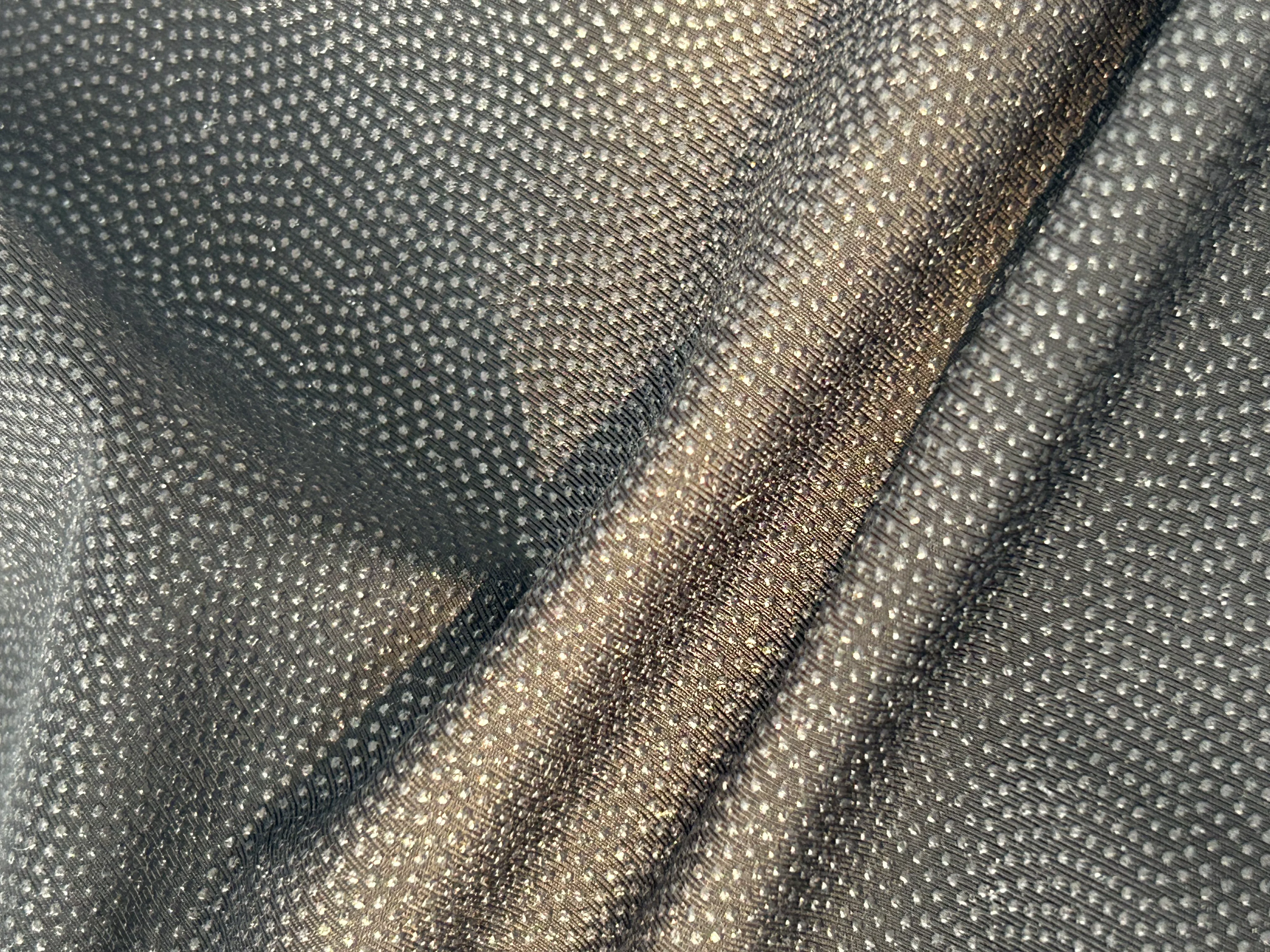

Functional Interlinings for Automotive Interiors: A Performance Analysis from Basic Safety to Comfort and Intelligence

This article analyzes high-performance automotive interior interlining, focusing on its core properties of enhancing heat dissipation efficiency, resolving breathability issues and preventing stuffiness. This material is widely adapted for seats, sunshades and the lamination of interior protective components, serving as a key solution for improving cockpit comfort and manufacturing craftsmanship quality.

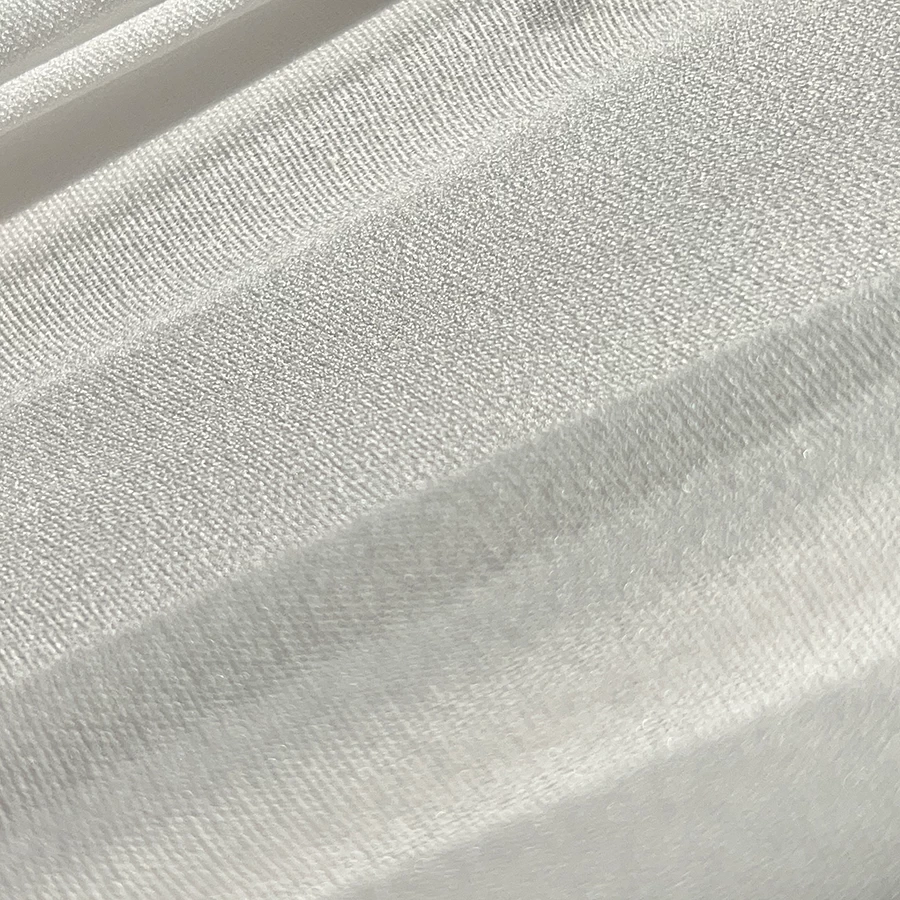

The "Invisible Framework" of Clothing: Why Do High-Quality Interlinings Require Anti-Slip Treatment?

Anti-slip treatment is the soul craftsmanship of high-quality interlining. Like an invisible structural adhesive, it penetrates and firmly locks the fabric yarns, preserving the fabric’s flowing hand feel while enhancing the garment’s seam strength and dimensional stability, making it an inherent guarantee for high-end fashion.

Fusible Interlining for Yoga: The "Invisible Strength" Empowering Modern Sportswear

Fusible interlining specially designed for yoga serves as the "invisible skeleton" of modern sportswear. With its precise shaping, extreme flexibility, and breathable, invisible performance, it solves technical problems such as pattern distortion and seam curling in highly elastic fabrics. It provides invisible support at key details like waistbands, logos, and sports bras, elevating wearing comfort and sports experience through "invisible" technology.

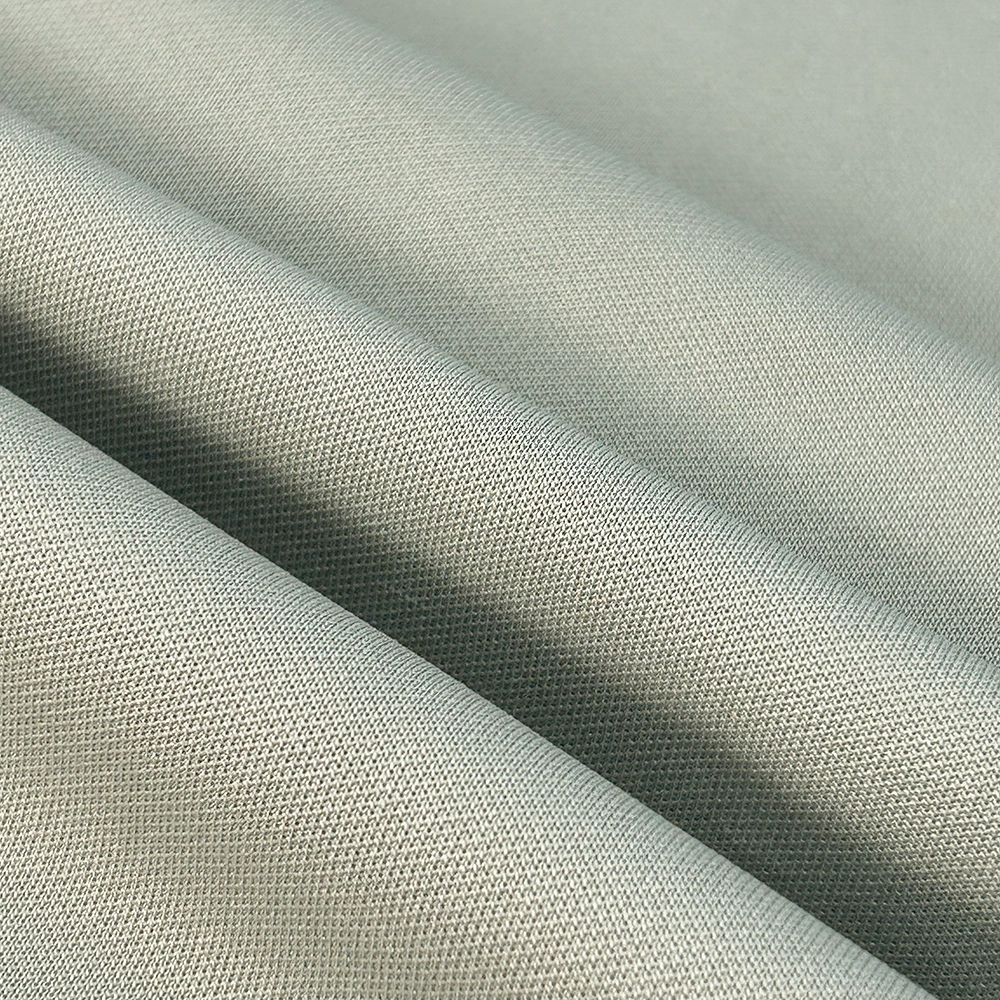

The "Second Skin" of Shirts: Polyester-Cotton Lining vs. Pure Cotton Lining

From the perspective of material properties: Pure cotton interlining for shirts is hygroscopic and skin-friendly, ideal for high-end casual wear; polyester-cotton interlining is wrinkle-resistant and shape-retaining, meeting the core demands of formal and uniform wear for crispness, durability and easy care.

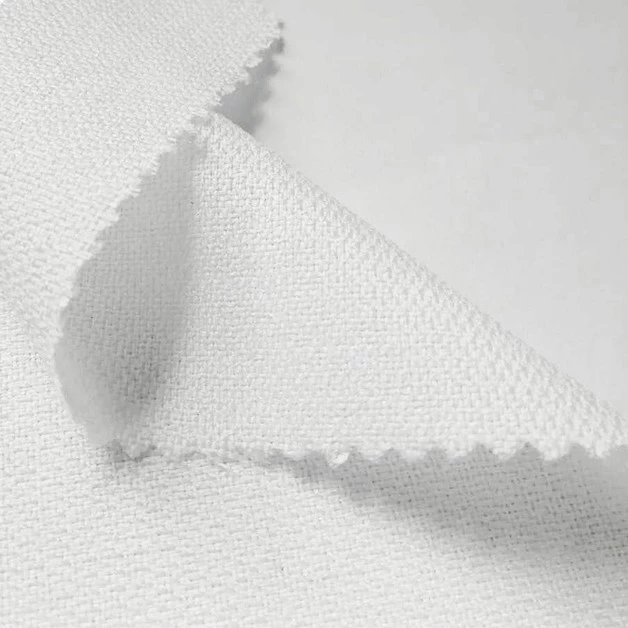

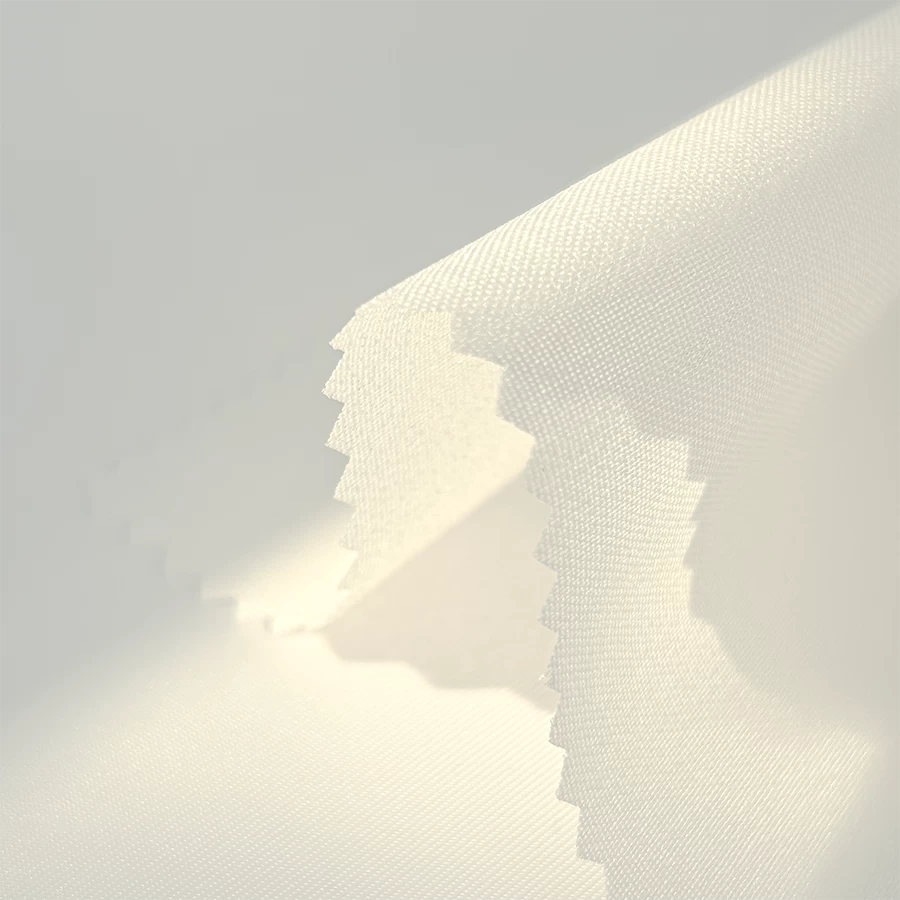

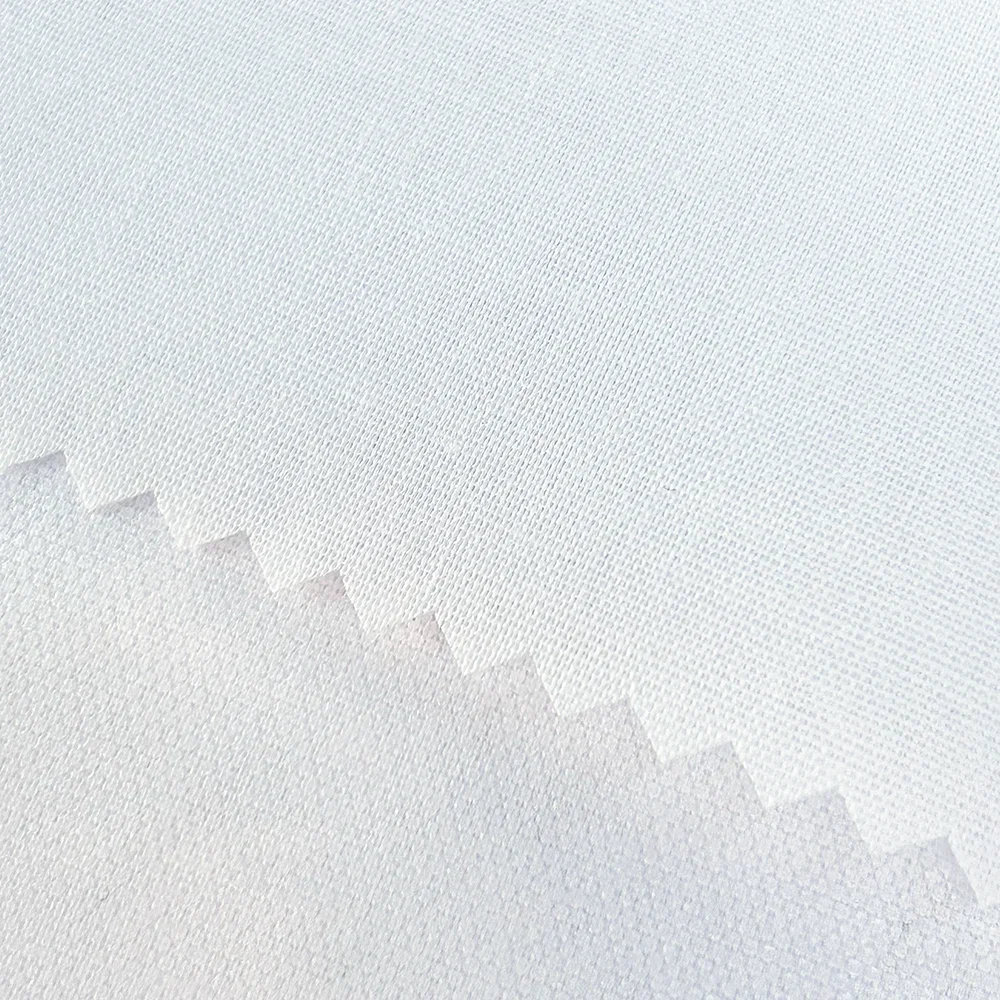

Non-Woven Fabric: Shaping Modern Life Without Weaving

Non-woven fabric, a new type of material without warp and weft interlacing, has been deeply integrated into fields such as medical protection, garment interlinings and daily necessities by virtue of its properties including breathability, lightweight and strong plasticity. This article will systematically interpret its process characteristics and practical applications.

Invisible Safety and Quality: How Fluorescent-Free Pocket Lining Interlining Becomes the "Internal Benchmark" for High-End Apparel

Fluorescent-free pocket lining interlining ensures no addition of migratory fluorescent brighteners through full-process production control. Its necessity is reflected in three core scenarios: safeguarding the safety of children's clothing, maintaining the color purity of high-end light-colored fashion apparel, and supporting eco-friendly brand concepts.