What are the tips for lining shirts?

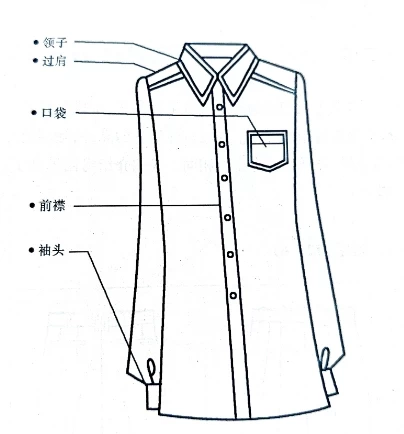

One of the common characteristics of shirts is that they are required to be resistant to washing (wrinkle and shrinkage). Therefore, the interlining fabric used is first of all wash-resistant interlining fabric. Cotton and polyester-cotton blended shirts, often using high-density polyethylene (HDPE) adhesive resin lining; pure polyester interwoven fabric shirts, can also use polyester (PES) adhesive resin lining; silk shirts using imitation silk (nylon) adhesive lining; knitted shirts using elastic adhesive lining. With lining parts of the collar, placket, cuffs, over the shoulder and pocket parts. Different parts of the lining varieties and functions are different. Collar using washable stiffening resin lining, the rest of the use of washable bonded lining. However, the collar is divided into single-layer and double-layer interlining.China Shirt Interlining suppliers

| NO. | Application area | Usage | Role of function |

| 1 | single layer on top collar | 0.2cm smaller than the neckline | Contouring, shape retention, firmness |

| 2 | double layered top collar | The second layer is smaller than the first | Contouring, shape retention, firmness |

| 3 | lower neck | The lining is slightly thicker and stiffer than the top collar | Contouring, shape retention, firmness |

| 4 | collar point | Attach to the lining with a strong liner | Stiffening, reinforcing |

| 5 | sleeve header | reinforcement lining | Stiffness, shape retention, beautification |

| 6 | lapel | Reinforcement long straight bushing | Stiffness, shape retention, beautification |

| 7 | reinforced fusible lining | Stiffness, shape retention, beautification |

Cotton non-iron shirt with lining, must have super-soft, low shrinkage, heat shrinkage, non-yellowing, washing resistance, good stability and feel good performance. Secondly, due to the full non-iron shirt in the gasification of black absorption process, to be 160 ~ 170 ℃ oven up to 6 ~ 7min (some even 12 ~ 13min), so pay attention to the bonding pressure ironing conditions need to be lower than the conventional ordinary shirts, i.e., the temperature is not higher than 160 ℃. So that after the oven after the overall bonding effect will reach the best. Otherwise, the gasification suction fumigation processed shirts, its adhesive strength decreased significantly, and accompanied by leakage, feel hard and other undesirable phenomena. In addition, the appearance of the quality of the interlining fabric should also be tested before cutting, such as knots, roving, oozing glue, yellow fishy odor, etc., if found, should be replaced.China shenghong interlining manufacturer