10 characteristics of knitted fabrics, a must for garment people

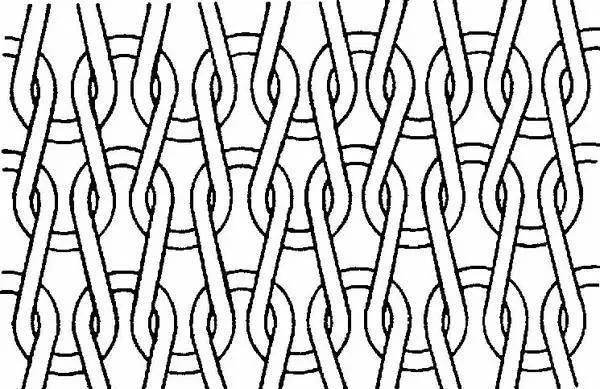

(1) Stretch: knitted fabrics are made of coils of string and become, by the external force, the coil in the circle column and circle arc “transfer, the disappearance of external forces can be restored. In the vertical and horizontal direction can occur. The degree of its occurrence and raw material varieties, elasticity, density, coil length and dyeing and finishing process.

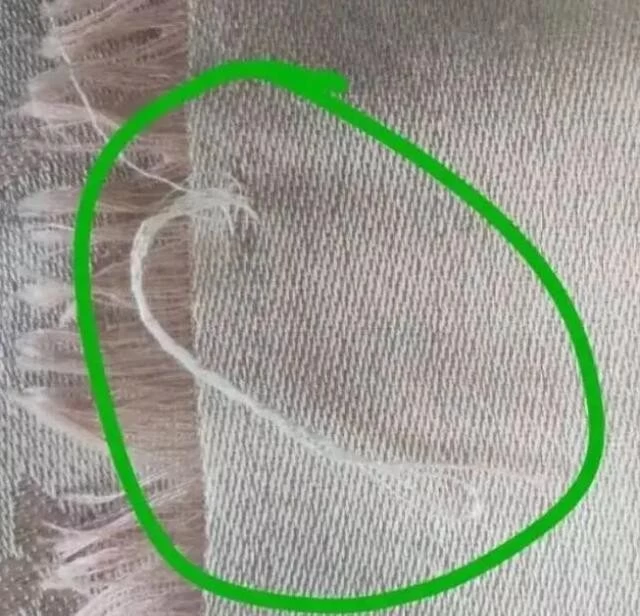

(2) Dispersion: when the knitted fabric yarn breaks or coil loss of string set connection, will occur in a certain direction of the final loop and coil separation, known as dispersion. Clothing sewing, such as the use of overlock, taut stitching to prevent dispersion, or the use of rolled edges and rolled edges, sole ribbed edges to prevent the edge of the fabric from dispersing. Fugitive and raw material types, yarn friction coefficient, organizational structure and yarn bending rigidity and other factors. Single-sided weft flat knitting organization dispersion is larger, jacquard fabrics, double-sided fabrics and warp knitting fabrics dispersion is small or not dispersed.China Good quality knitted interlining suppliers

(3) Crimp: single knitted fabrics in the free state, the edge will appear wrapped phenomenon, known as crimp. In sewing, the crimp will affect the sewing operation speed, reduce operational efficiency. At present, foreign countries use spray adhesive sprayed on the edge of the cut fabric to overcome the phenomenon of crimping. The hemming is related to the organizational structure, yarn twist and loop length and other factors. Single knitted fabrics and double knitted fabrics obvious crimping phenomenon without crimping.

(4) Breathability: knitted fabrics of the coil structure can save more air, and thus breathable, comfortable to wear

(5) Moisture absorption: knitted fabrics of the coil space is large, so that its moisture absorption is good, warmth is also good, feel comfortable.

(6) Easy hooking: in wearing, washing, a touch of hard objects, the yarn will be hooked out, said hooking.China Garment Interlining Source Factory

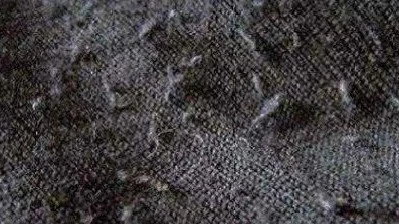

(7) Hairball: friction makes the fiber end of the fabric surface exposed to the surface of the fabric, called hairy. When the hairy fiber

When the end of the fibers do not fall off and entangled with each other to be kneaded into small particles, known as pilling. Extra attention should be paid to this when tailoring.

(8) Shear resistance: First, the silk fabric is soft, smooth, electric knife when cutting, easy to make the upper and lower layers of the slip offset, resulting in size errors; Second, cutting chemical fiber fabrics, knife speed leads to fiber friction due to heat fusion, bonding. Therefore, paving clamping, not easy to be too thick, knife speed should be decelerated.

(9) Weft skew: knitted fabrics vertical and horizontal direction is not perpendicular to the weft skew. Weft skew is mainly caused by the twist of the knitting yarn. Multi-way knitting will make the weft skew aggravated.

(10) Retraction: knitted fabrics in the cutting, bonding, sewing, length and width will occur to a certain degree of retraction. The amount of retraction and the original design size of the proportion called process retraction rate. Shrinkage is an important feature of knitted fabrics, the design of clothing and the production of samples to consider the parameters of its shrinkage.