The Secret of Fusible Interlining: How Peel Strength Determines Garment Longevity

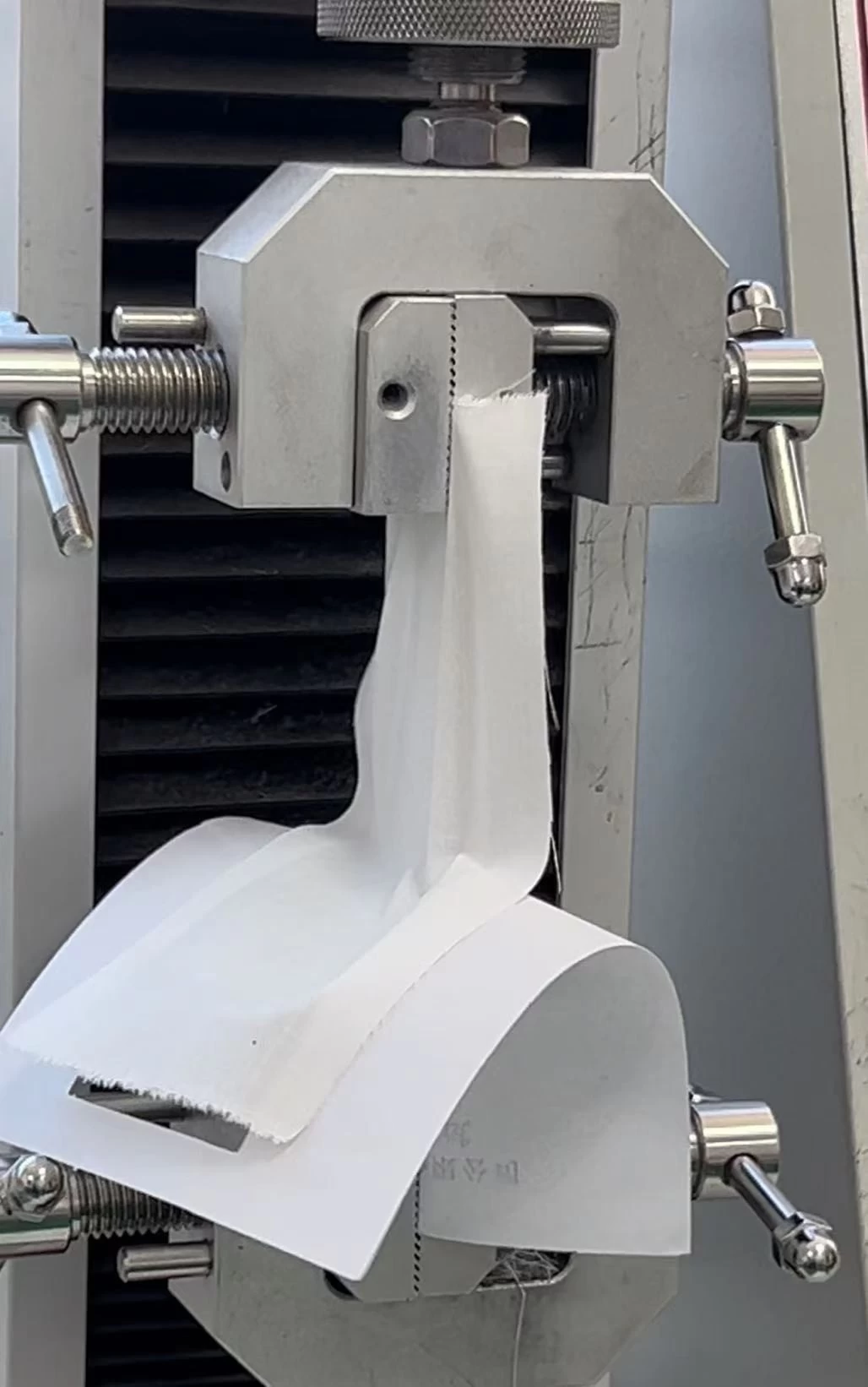

Peel strength refers to the bonding village and the bonded fabric peeling force required, is an important indicator of the examination of adhesive strength of the adhesive lining. Through the test peeling strength, as long as the requirements of the prescribed standards, the adhesive strength of the adhesive lining is no problem, but not the higher the peeling strength is better. Peeling strength is divided into: peeling strength after bonding after washing peeling strength; dry cleaning peeling strength; steam peeling strength. Usually we call the peeling strength after bonding the initial strength or original strength; washing, dry cleaning and steam peeling strength, reflecting the degree of durability after bonding, generally lower than the original strength, the greater the intensity of the weakening, indicating that the worse the durability. In the production of fusible interlining and apparel interlining processing, the first application of fusible interlining, in addition to the determination of the original strength of the bond, for the other three aspects of the peel strength, at least one of the indicators should also be determined. Normal production, at any time to test the peel strength after bonding can be sampled. The original peel strength after bonding is generally not less than 10N/2.5cm (width).shenghong interlining factory China

Factors affecting the peeling strength are as follows

A. the size of the amount of coating: the larger the amount of coating peeling strength is higher. But too high will make the feel hard and easy to leakage.China interlining manufacturer

B. The influence of the base cloth: the base cloth fiber type, tissue specifications, pre-finishing and so on.

C. Physical and chemical properties of hot melt adhesive: bonding properties of hot melt adhesive, thermal fluidity properties, powder properties, etc.

D. Coating method: uniformity of coating distribution, geometry, density of adhesive particles, transfer of adhesive particles, melt state, etc.

E. Fabric properties: fabric fiber type, reverse surface finish, whether by resin finishing or silicone oil finishing

The fabrics have been finished by resin finishing or silicone oil finishing.

F. Ironing process: ironing conditions (mode, equipment, temperature, pressure and time, etc.) of the impact.China interlining source suppliers