How to test the quality of interlining fabric?

I. Appearance Inspection

1. Flatness

The surface of a good lining should be flat and smooth. Lay the interlining fabric on a flat table, gently touch the surface of the interlining fabric with your hand to check whether there are wrinkles, unevenness or hard lumps. For example, a high-quality shirt lining has no undulations on the surface and fits the fabric well. If the interlining has obvious wrinkles, it will affect the appearance of the garment during use, resulting in an uneven surface.

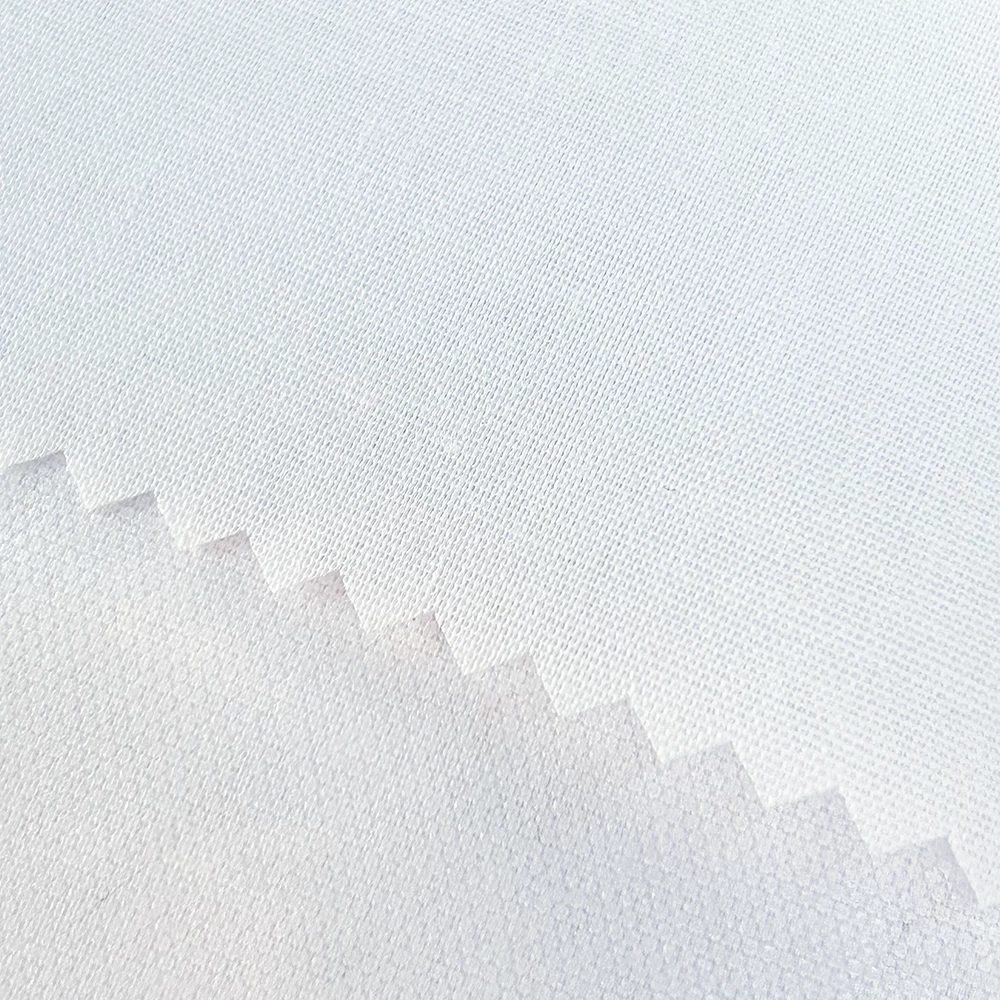

2. Color uniformity

Observe whether the color of the interlining is even. Uneven color of the interlining may be caused by poor dyeing process or poor quality of raw materials. You can view the color of different parts of the interlining in normal light to ensure that there is no color difference, color spots or fading phenomenon. For example, white interlining should be white and flawless, no yellowing or local discoloration; black interlining color should be pure, no gray patches.

3. Fabric blemishes

Carefully check the interlining fabric for knots, holes, missing yarns and other defects. These defects will affect the strength and appearance of the interlining. The interlining can be viewed against the light, the knot will form a clear bulge in the light, and the holes will have the phenomenon of light transmission. For example, in the production of high-end garments, even a small knot may form a bulge on the surface of the garment, affecting the wearing experience and the quality of the garment.Textile manufacturer china

II. Physical Property Test

1. Thickness and weight

The thickness and weight of the interlining need to meet certain standards. Thickness can be measured with a thickness meter, and interlining fabrics for different purposes have different thickness requirements. For example, the thickness of interlining used for light summer garments is thin, generally between 0.1 - 0.3 mm; while the thickness of interlining used for winter jackets may be 0.5 - 1 mm.

Weight can be determined by weighing the fabric. The right weight ensures that the interlining is strong without overloading the garment. In general, the more uniform the weight of the interlining per unit area, the better the quality. If the weight of the interlining varies greatly, it may lead to inconsistencies in the feel and stiffness of different parts of the garment.

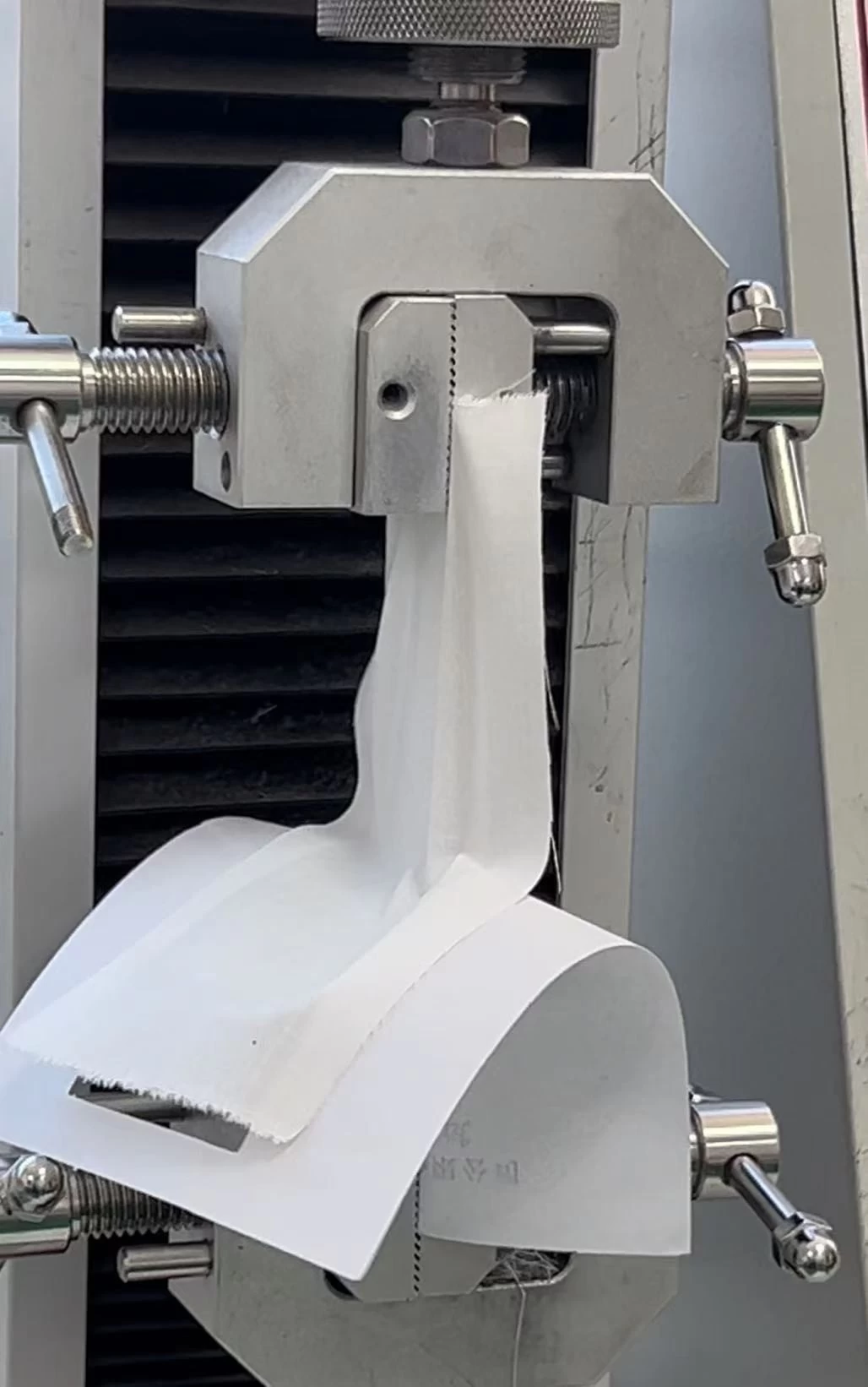

2. Strength Test

Tensile strength is an important indicator of interlining quality. You can take a small section of the interlining and use a tensile testing machine to perform a tensile test to observe how much the interlining will break under tension. High-quality interlining should have a high tensile strength, able to withstand a certain degree of tension without breaking. For example, interlinings used in parts of a garment that are susceptible to pulling, such as the neckline and cuffs, need to have good tensile strength, otherwise they can be easily damaged during wear.

Tear strength is also critical. Tested by simulating a situation where the interlining is torn, a good interlining should be more difficult to tear and have a neater tear. If the lining fabric has poor tearing strength, it may be torn by a slight external force during the garment production process or when wearing, reducing the service life of the garment.

3. Shrinkage test

Soak the interlining sample in water for a period of time, then take it out to dry and measure its size change. Generally speaking, the shrinkage rate of high-quality interlining fabric should be relatively low. For example, interlining fabric with a shrinkage rate of less than 3% is of good quality. If the shrinkage rate of the interlining is too high, the interlining will shrink after the garment is washed, resulting in deformation of the garment and affecting the fit and appearance of the garment.China non-woven interlining suppliers

Third, chemical performance test

1. Acid and alkali resistance test

Different pH environments can be simulated to test the tolerance of the interlining. Soak the interlining fabric in acidic and alkaline solution for a period of time, and then observe the color of the interlining fabric, strength and other performance changes. A good interlining cloth should be able to maintain stable performance within a certain range of acidity and alkalinity, without fading color, a significant drop in strength and so on. For example, the interlining used in some garments that require special cleaning (such as work clothes that may come into contact with chemical reagents) requires a high degree of acidity and alkalinity resistance.

2. Environmental indicators test

Detect whether the interlining meets the environmental standards, such as whether it contains formaldehyde and other harmful substances. Formaldehyde is a common hazardous substance, will cause harm to human health. You can use professional testing equipment to detect the formaldehyde content in the interlining, in line with national environmental standards (such as formaldehyde content below a certain limit) of the interlining is the quality of qualified. At the same time, you can also test whether the interlining contains other harmful chemicals, such as heavy metals.shenghong interlining factory china