How to make waist lining more durable?

In the field of garment production, waist lining is a key element in shaping the waist line and maintaining the shape of the garment, and its durability directly affects the quality and wearing experience of the garment. So, how can we make the waist lining more durable? The following advanced technologies provide the answer.

Hot melt adhesive composite technology is an important tool to enhance the durability of waist lining. The traditional way of combining waist lining and fabrics is prone to delamination after repeated washing, which not only destroys the overall appearance of the garment, but also greatly shortens the service life of the waist lining. The emergence of hot melt adhesive composite technology perfectly solves this problem. Through precise control of the amount of hot melt adhesive and application position, under the action of high temperature and high pressure, the waist lining and fabrics are closely fused together. As a result, a strong connection is formed between the waist lining and the fabric, which has excellent washing resistance. Whether it is the frequent washing of daily wear, or more powerful cleaning process, it is difficult to make the two separated, thus ensuring that the waist lining in the garment life cycle always play a stable role. China shenghong Waist Lining factory

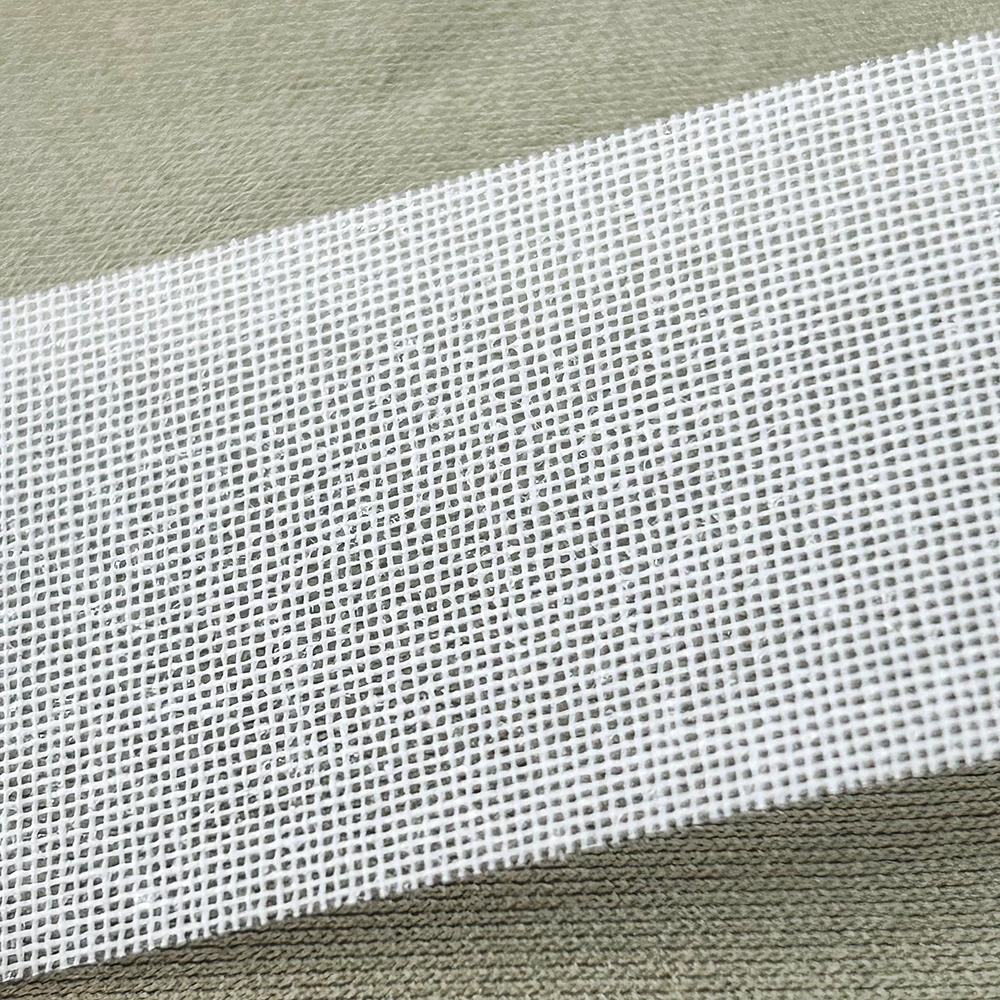

The warp and weft knitting processes provide structural support for the durability of the waist lining. Different garment styles have different elasticity requirements for waist linings. Warp knitting optimizes the structure of the waistband lining and gives it good longitudinal elasticity. For garments that emphasize a slimming effect and have a large amount of activity, such as sports-style skirts or pants, warp knit waist lining can ensure that the waist fits without binding due to the human body's flexion and extension movements, and still maintains its own structural stability and is not easy to deform during repeated stretching. The weft knitting process focuses on improving the lateral elasticity of the waist lining, which is suitable for garments that need to create a loose or special shape at the waist. This optimization of elasticity in different directions allows the waist lining to better adapt to the needs of various garments and maintain its durability in different wearing scenarios. Waist lining manufacturers in China

Laser cutting technology brings both durability and wearing comfort to the waist lining. In the traditional production process, although the sewing method can realize the connection between the waist lining and the garment, the stitching line often produces a bulge, which not only pinches the skin when wearing and affects the comfort, but also tends to lead to localized damage of the waist lining in the process of long-term friction and reduces the durability. Laser cutting technology realizes a seamless fit between the waist lining and the fabric. It instantly melts or vaporizes the cut area by means of a high-energy laser beam, leaving the edges smooth and flat without any unwanted threads or bumps. This not only avoids pinching problems, but also reduces wear and tear due to friction, allowing the waist liner to maintain its functionality and durability in a more complete form during daily wear and washing. China professional production of waist lining manufacturers