An in-depth look at hat liners: functions, materials and selection of applications

First, the function of the hat lining fabric

1. Shape the hat

One of the most basic and important functions of a hat liner is to shape and maintain the shape of the hat. Whether it is a fashionable baseball cap, an elegant beret, or a classic bowler hat, the right lining fabric can help the hat present the shape desired by the designer. For example, in the case of a baseball cap, the lining on the top of the cap needs to be hard and stiff in order to support the three-dimensional shape of the cap and keep it rounded and full, without collapsing. For beret such a soft hat style, the lining fabric should ensure a certain degree of flexibility at the same time, to give the hat appropriate support, so that it can fit the head contour, showing a unique elegant flavor.

2. Enhance the durability

Hat in the daily wear and use process, will be subject to a variety of external forces, friction, and wind and sun and other environmental factors. Hat lining can play a reinforcing role, greatly enhancing the durability of the hat. It can share part of the pressure borne by the outer fabric of the hat, preventing the fabric from being deformed and broken due to excessive force. For example, in the production of outdoor sun hat, the durability of the lining fabric is particularly important, because these hats are often frequently used, and may come into contact with branches, rocks and other sharp objects. High-quality lining fabric can effectively resist the impact of these external forces, extending the service life of the hat and providing consumers with longer-lasting use value.

3. Improve wearing comfort

The lining fabric also affects the wearing comfort of the hat to a large extent. It can be used as a buffer layer to reduce the direct stimulation of the scalp of the outer fabric of the hat. Especially for some of the material is more rough hat fabric, the lining can play a soft transition role, so that the wearer feels more comfortable. In addition, some lining fabrics with special functions, such as sweat-absorbent lining fabric, can quickly absorb the sweat secreted by the scalp, and conduct it to the outer fabric, accelerate the evaporation of sweat, keep the head dry, avoid the discomfort caused by the accumulation of sweat, and enhance the wearing experience.China hat interlining suppliers

Second, the material characteristics of the hat lining fabric

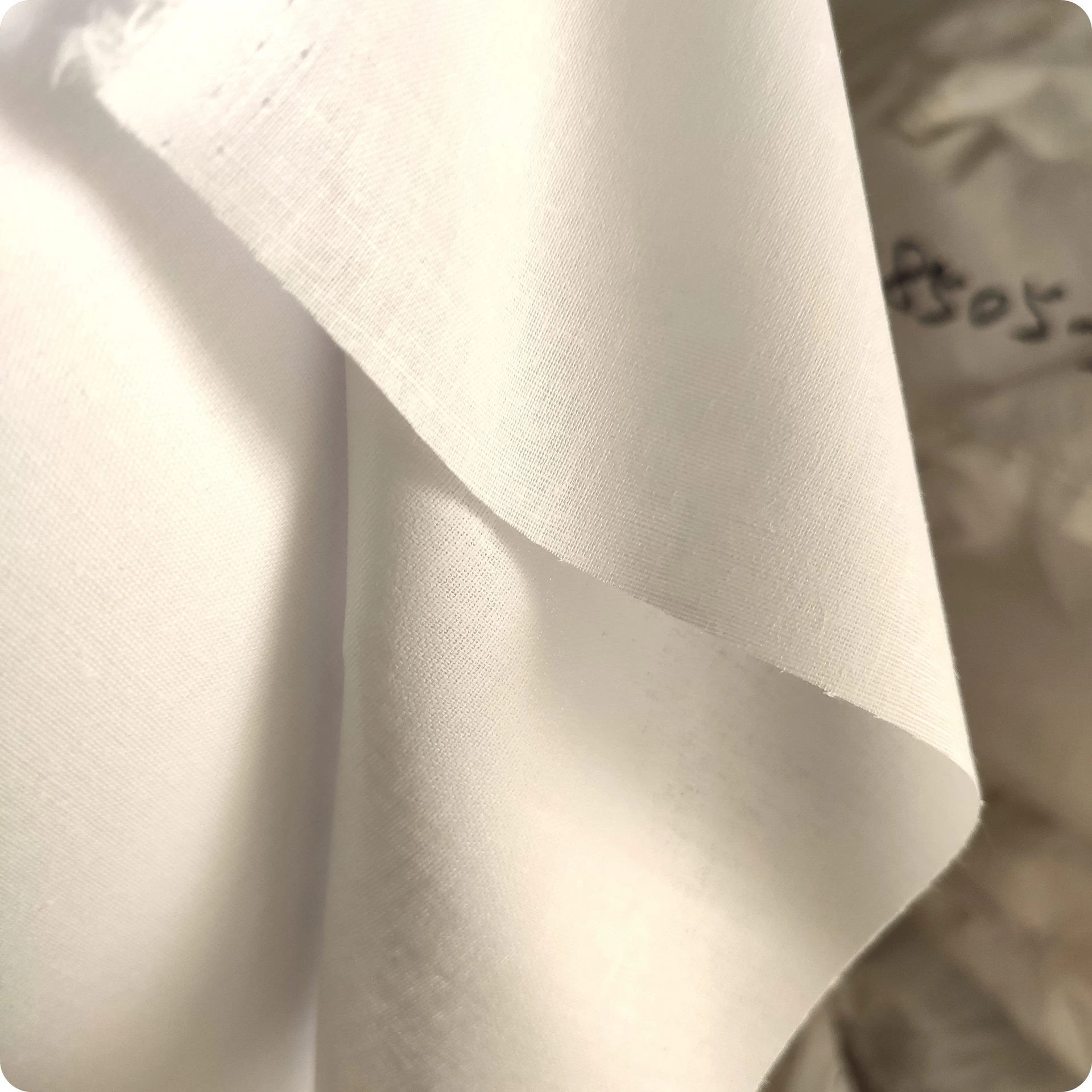

1. Cotton lining

Cotton lining is made of natural cotton, which is soft, comfortable and moisture-absorbent. It is friendly to the skin, will not cause allergies and other uncomfortable reactions, is very suitable for making close to the scalp of the hat lining. Cotton liners absorb sweat well and keep your head dry, while their soft texture provides a comfortable wearing experience. However, cotton lining is relatively low-strength and may be less suitable in areas that require a higher level of support. Moreover, it is prone to shrinkage and needs to be pre-shrunk during the manufacturing process.

2. Chemical Fiber Interlining

Chemical fiber interlining is usually made of polyester, nylon and other chemical fibers. This kind of interlining fabric has the advantages of high strength, good stiffness, not easy to shrink and deformation. Polyester interlining is relatively inexpensive and has good abrasion resistance and wrinkle resistance, which can provide long-lasting support and stable shape for the hat. Nylon interlining, on the other hand, has excellent elasticity and abrasion resistance, and is often used for hats that require frequent movement, such as sports caps. However, chemical fiber liners have relatively poor breathability and moisture absorption, which may make your head feel stuffy when worn for long periods of time.

3. Blended interlining

Blended interlining is made by mixing natural fibers and chemical fibers in a certain proportion. It combines the advantages of both, both with the soft and comfortable cotton lining and moisture absorption, but also with the strength and stiffness of chemical fiber lining. For example, cotton-polyester blended interlining, with the skin-friendliness and sweat-absorbent ability of cotton and the wrinkle-resistance and durability of polyester, can meet the needs of hat-making in different ways. The performance of blended interlinings can be adjusted according to different fiber ratios, thus occupying an important position in the hat interlining market.China hat interlining wholesales

Third, the choice and application of hat lining

1. According to the hat style selection

Different hat styles have different requirements for lining fabric. For the need to shape and maintain the hard shape of the hat, such as baseball caps, duck tongue cap, etc., should choose a higher hardness, good stiffness of the lining fabric, such as hot melt lining with woven lining or thicker non-woven lining. For soft, close to the head of the hat, such as beret, knitted cap, etc., is suitable for the use of high softness, good flexibility of the lining fabric, such as light non-woven lining or cotton lining.

2. Consider the use of the hat

If the hat is used for outdoor activities, such as hiking, fishing, etc., it is necessary to choose a lining fabric with waterproof, breathable and wear-resistant functions to adapt to the complex outdoor environment. For example, the use of non-woven lining fabric with waterproof coating can ensure the breathability of the hat and prevent rainwater penetration. For the daily wear of fashion hats, you can pay more attention to the matching effect of the lining fabric and fabric, as well as wearing comfort, choose soft, skin-friendly and can enhance the overall aesthetics of the hat lining fabric.

3. Combined with the cost factor

In the choice of hat lining, the cost is also an important consideration. Different types and materials of lining fabric price difference. Under the premise of ensuring the quality of the hat, enterprises can make a reasonable choice according to their own cost budget. For some low-end market hat products, you can choose a lower cost but performance to meet the basic needs of non-woven interlining or ordinary chemical fiber interlining. For high-end products, they can choose high-quality woven interlining fabric or special function interlining fabric to enhance the added value of the product.

Although the hat lining may seem inconspicuous, but in the production process of the hat plays a pivotal role. It is not only about the appearance and durability of the hat, but also directly affects the comfort of the wearer. With the continuous progress of science and technology and the increasing demand of consumers on the quality of hats, the types and performance of hat linings are also constantly innovating and developing. Both fashion brands and hat manufacturers should fully recognize the importance of hat lining, choose the right lining according to different needs, and create more high-quality, stylish and comfortable hat products for consumers.China hat interlining manufactures