Comparison of the main coating processes for interlinings

In the field of modern garment manufacturing, interlining, as an indispensable garment accessory, its performance and quality play a key role in the overall effect of the garment. The coating method largely determines the quality of the interlining. Different coating methods have their own characteristics, from equipment investment to product quality, from production efficiency to the scope of application, there are differences. The following is a detailed comparative analysis of various coating methods for interlining production, such as powder coating method and powder coating method, to explore their uniqueness and application boundaries in interlining production.China interlining manufacturer

| Coating method | Key Benefits | Main drawbacks | Scope of application |

| Powder coating method | Simple structure of the equipment, less investment capital, easy operation and wide applicability. | Insufficiently uniform coating, high powder consumption at the same peel strength | Suitable for lower grade products |

| Powder Dot Coating Method | Good quality of processed products, low production cost, many product specifications | Higher technical requirements for equipment maintenance operations | Suitable for direct bonding of interlining for all kinds of garments, not suitable for non-woven fabrics. |

| Slurry Spot Coating Method | Good product quality and adaptability. | Complicated production preparation, slightly higher energy consumption and production costs | Suitable for all types of interlining |

| Molten Glue Dot Method | Simple equipment, low cost, no need to make powder for molten rubber | Narrow adaptability, special requirements for hot melt adhesives | Suitable for low melt viscosity hot melt adhesive coatings, mainly for outerwear bonding interlining. |

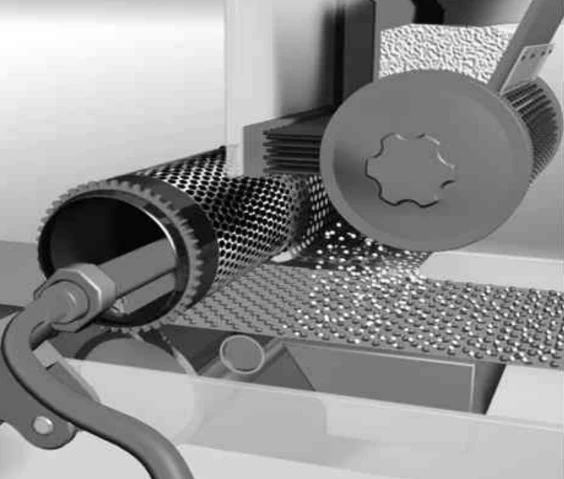

| Double Dot Coating Method | Excellent product quality, high adaptability, wide range of pressing and processing conditions | More complex technology, higher equipment and production costs | Suitable for garment interlining with high quality requirements and difficult bonding. |

| Thin Film Coating Method | Good product quality, simple equipment structure, no need to make flour | Narrow adaptability, special cracked film required | Suitable for shirt fusible interlining |

It is worth mentioning that the production line of our Sheng Hong factory adopts the double-dot coating process. This process can better meet the market demand for high-quality interlinings due to its significant advantages such as excellent product quality, high adaptability and wide range of pressing conditions. In the highly competitive apparel accessories market, we are committed to providing customers with high-quality and stable performance interlining products by virtue of the double-dot coating process, which helps apparel production realize higher quality standards.China shenghong interlining manufacturer