Basic Characteristics of Hair Lining

The warp yarn of woolen interlining base cloth is usually made of fine cotton yarn or double stranded yarn, such as 42s/2, 32s/2, 30s/2, and sometimes 16s cotton yarn treated with sizing, the thickness and fineness of the yarn mainly depend on the number of counts of woolen yarns in the weft direction, and the organizational structure is usually thinner, which can maintain the warp stiffness.

The weft yarn of wool lining is generally made of thicker animal fibers as the core yarn of fancy yarn (wool yarn), or yarn blended with other fibers such as rayon. For example, yak hair + human hair + viscose fiber blended yarn, goat hair + a small amount of yak hair + viscose fiber blended yarn. The elasticity and flatness of the base cloth woven with goat hair yarn is better, while the stiffness of the base cloth woven with yak hair yarn is better, but the shrinkage rate is not easy to control in the finishing process. The count of wool yarn is expressed in metric Nm, generally there are thicker 7.5Nm, 10Nm, finer 11.5Nm, 13Nm.

Woolen lining fabric fabric organization is generally plain, woven on rapier looms, there are also satin structure of its front is plain structure, the reverse side is satin structure, which is based on its different uses and decisions. Such as for fixed-sleeve cotton, because it is cut on the bias, and the plain structure of the wool lining does not have stretch elasticity, not to facilitate the stretch and swing of the sleeve, so in the selection of wool lining, consider the use of the front side of the plain structure, the reverse side is the satin structure (used for fixed-sleeve cotton outside the circle) of the wool lining, used to ensure that its wearing performance. Therefore, the fabrics woven according to the above selection of materials and weaving methods have different tensions between the warp and the weft, i.e., the warp direction has a snug and firm fit, while the weft direction has a firm and stretchy fit.

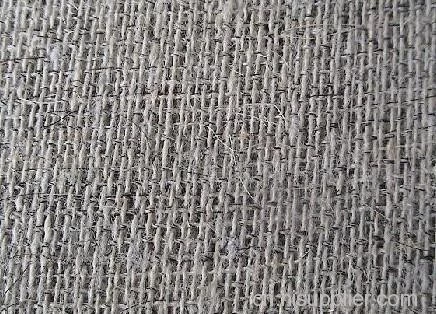

Woolen interlining is a traditional interlining fabric with brownish-black appearance (now there are woolen interlining dyed black), coarse and astringent, good stiffness and outstanding elasticity, mainly used for suits, coats and other outerwear in the front (including women's chest lining), cover the shoulders, the sleeve hole parts, so as to make the upper part of the garment more upright, with a good drape, is a kind of special interlining fabric that can enhance the sense of fullness of the clothing (the shoulder and chest position of the blouse) and the sense of comfort in wearing.

Another high-grade wool lining for the core ponytail lining, the warp is still using cotton yarn, weft with ponytail mane. At the beginning, people in the weaving, the horsetail mane as the weft yarn fed into one by one, the width of the base cloth by the length of the horse's tail limitations, low efficiency, and the use of waste (not cost-effective). With the development of science and technology, the use of the production of cable technology, with three 45s cotton yarn wrapped horse tail, manufacturing artificial horse tail yarn, so that the limited length of the horse tail, can weave any width of the base cloth, greatly improving the utilization rate, but the cost is higher. Ponytail lining is rigid, elastic and relatively light, it is a special chest lining, mainly used for all kinds of high-grade suits and coats of the chest and shoulders.

When the lining is used in the chest of the front body of suits, coat suits and other garments, in order to create its beautiful shape and satisfactory wearing comfort, it is necessary to change the tension of the lining according to the different parts. For example, when used for the shoulder, a piece of black charcoal lining on the other appropriate thickness of the small enhanced lining (called cover shoulder lining) as a reinforcement of the wool lining.China non-woven interlining suppliers