Automotive interior mesh application analysis: from comfort to safety of multi-dimensional empowerment

I. Seating System: The “Golden Pair” of Breathability and Support

(I) 3D Mesh Fabric - Reinventing the Comfort Experience

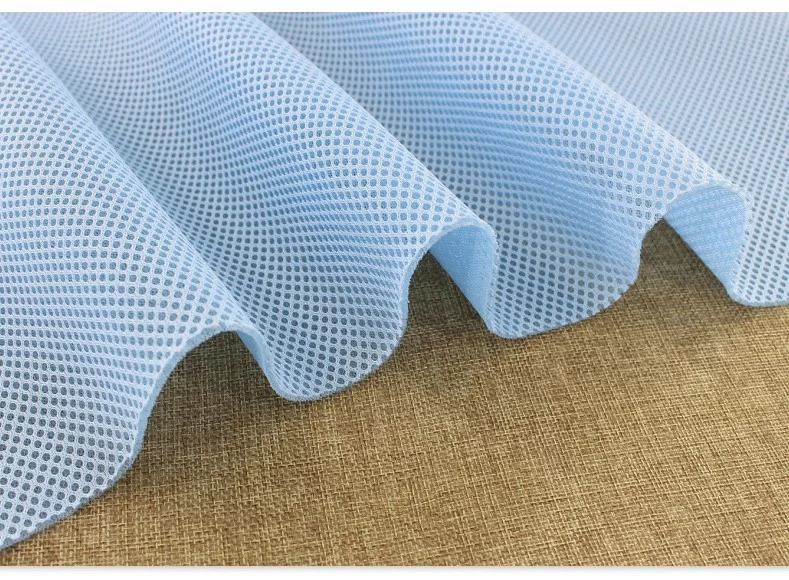

3D mesh fabric (such as extra thick sandwich mesh fabric) is one of the core materials of the seat. It is made of high polymer synthetic fiber woven by precision machine, presenting a double-layer mesh + middle monofilament vertically arranged structure:

1. Breathable and moisture permeable: the double-layer mesh forms air circulation channels, and with the car seat ventilation system, heat and moisture are quickly exported. Experimental data show that compared with the traditional sponge seat, 3D mesh seat can reduce the temperature of the driver's back and buttocks by 3 - 5 ℃, and humidity by 15% - 20%, goodbye to hot and sweaty.

2. Elastic support: the middle monofilament is arranged vertically at X-90°, with a density of 800 times that of a spring, evenly dispersing the pressure. Even after a long time of riding, the surface of the seat can be maintained flat, reducing fatigue, and at the same time avoiding the feeling of foreign matter brought by the ventilation structure, combining elasticity and support. shenghong Automotive interior mesh fabric factory China

(B) Functional Mesh Expansion Applications

1. Waterproof and breathable mesh: Some seats of high-end models adopt waterproof and breathable mesh, which can quickly block liquid splashes and expel water through the breathable structure to keep the seats dry, which is suitable for the rainy season and drink spillage scenarios.

2. Flame-retardant mesh: in line with automotive interior safety standards, it is not easy to burn in case of open flame, or can slow down the spread of fire, fighting for escape time for drivers and passengers, and building a safety line of defense in high-temperature sun exposure, circuit short circuit and other potential risk scenarios.

Instrument panel: “Innovative fusion” of design and practicality

3D - Mesh Mesh (3D mesh upgraded application) brings changes to the instrument panel:

1. Technological advantage: The use of negative mold vacuum molding, positive molding and other processes can realize the design of skin and mesh fabric without weakening. Compared with the traditional plastic lining process, the perceived quality is better, solving the bottleneck of manual wrapping which is difficult to meet the airbag point-blast experiment, and adapting to the personalized and diversified design needs.

2. Structure and performance: The instrument panel 3D-Mesh wrapping product consists of a skin layer (PVC/PU, etc.), a 3D-Mesh mesh layer, and a skeleton layer (PP/ABS, etc.). The breathable and elastic qualities of the mesh layer, together with the texture of the skin layer and the support of the skeleton layer, make the instrument panel both beautiful and practical, while the lightweight design helps to reduce the weight of the body and improve fuel economy. lining manufacturers in China

Third, other interior scenes: comprehensive penetration of the “details of the upgrade”

(I) Automobile Sunshade

The black mesh cloth protects the privacy of the car by virtue of the **dark room effect + one-way perspective principle** (it is difficult to peep outside the car, and it is clear to see outside the car); the small hole imaging ensures the line of sight, and it can effectively block the light, insulate the heat, and prevent ultraviolet rays, protect the interior facilities (such as the dashboard, leather seats), reduce the risk of deterioration and deformation due to the high temperature, and enhance the safety of the car (to reduce the interference with the line of sight of the direct sunlight).

(ii) Foot mats, headliner, etc.

1. Foot mats mesh: part of the sandwich mesh, three-layer composite structure (outer layer of environmentally friendly materials + intermediate mesh + inner layer of non-slip layer), breathable and wear-resistant, easy to clean and take care of, stains can be washed out with the water flow, reducing the growth of bacteria.

2. Roof mesh: lightweight, good dimensional stability, plump and beautiful surface, both sound insulation and heat insulation auxiliary function (with other soundproofing materials to further reduce the noise inside the car, blocking heat), to enhance the quietness and comfort of the driving environment.

Fourth, cutting-edge trends: materials and technology, “two-way breakthroughs”

(A) composite mesh innovation

Nylon fabric composite TPU membrane composite mesh has been used in high-end models (such as BMW's new X series, Ford's new F series). The multi-layer structure gives it good mechanical strength, the TPU film barrier realizes sound insulation (sound insulation amount reaches more than 25dB), and the multi-layer design is effective in heat insulation, and at the same time, it is environmentally friendly and recyclable, which is in line with the concept of sustainable development of the automobile manufacturing industry.

(II) Exploration of intelligent mesh

In the future, the mesh may be integrated into intelligent sensing technology, such as monitoring seat pressure distribution, temperature and humidity data, linkage of automotive intelligent systems (automatic adjustment of seat ventilation, air conditioning), so that the interior mesh from the “passive function carrier” upgraded to “active intelligent interaction unit “further reshaping the boundaries of automotive interior experience.

From basic functions to innovative applications, from single components to vehicle synergies, mesh is being deeply integrated into the automotive interior ecology with the keywords of “breathable, supportive, safe and intelligent”. With the iteration of material technology and the development of automotive intelligence, the application of mesh in automotive interiors will continue to make breakthroughs, creating a more comfortable, safe and intelligent travel space for users. Automotive interior mesh fabric wholesales