Mesh film double-sided adhesive backing process: revolutionizing textile bonding technology

In the textile industry's constant pursuit of innovation and efficiency, the mesh film double-sided adhesive backing process is emerging as a new revolution in the bonding and processing of fabrics. This advanced process, with its unique technical characteristics, is gradually changing the production mode of clothing, home textiles and other fields.

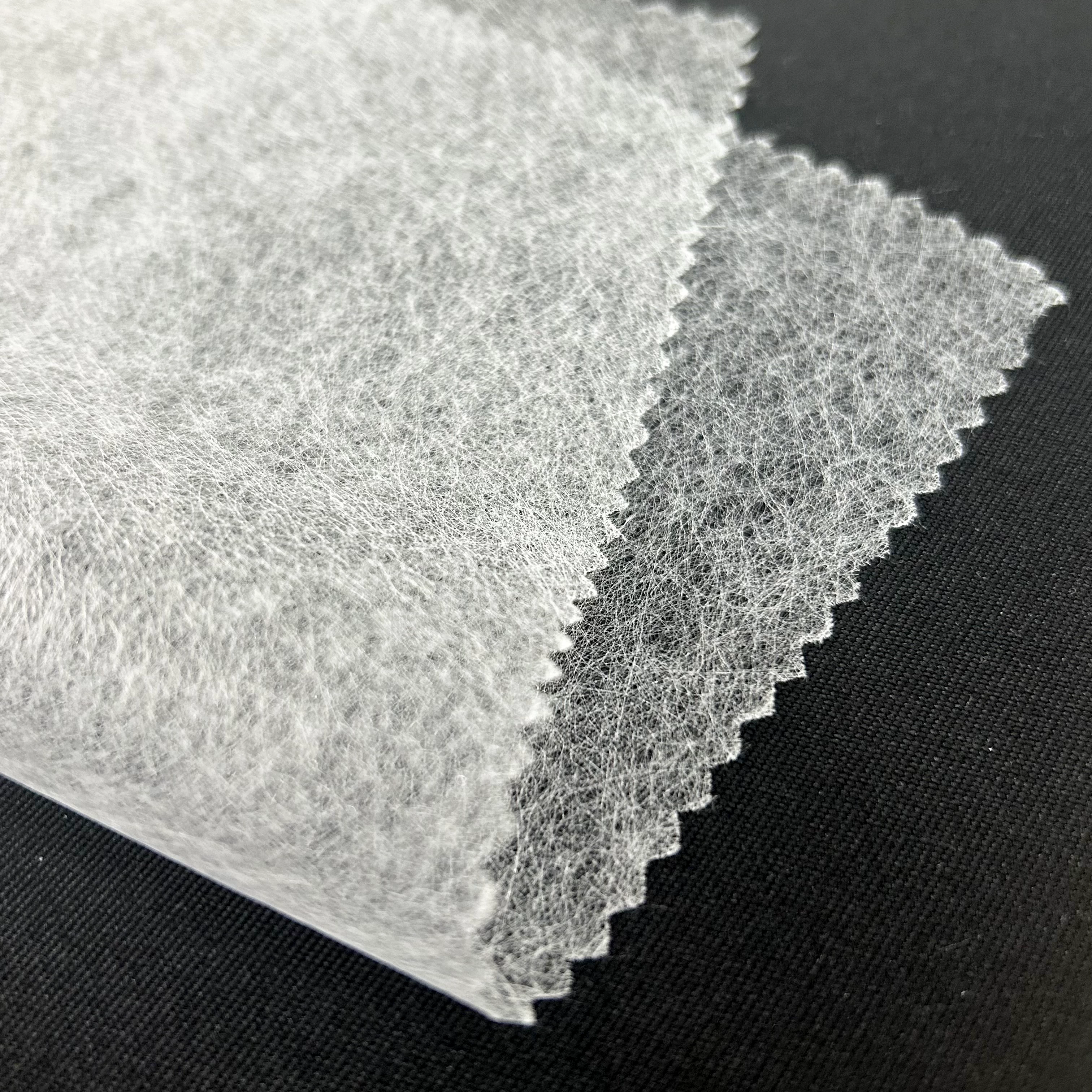

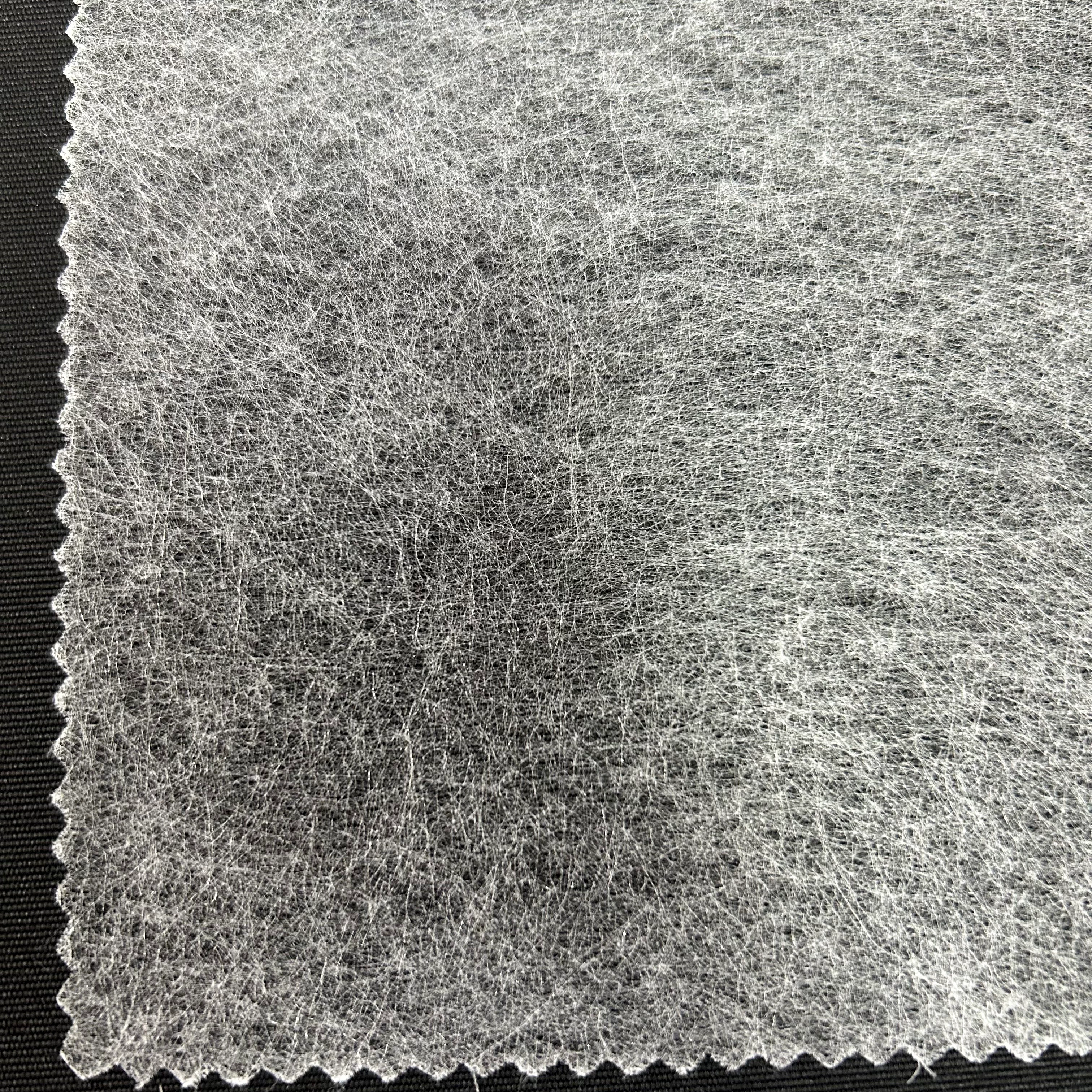

Mesh film double-sided adhesive interlining, in essence, is a special hot melt adhesive products, the appearance of its net-like structure, in the state of room temperature, it is like ordinary fabric as quiet to stay, not sticky, but once heated, it will quickly “active” up, double-sided instantaneous generation of strong adhesion, can be solidly two or more layers of fabric tightly pasted together. It can firmly stick two or more layers of fabrics together. This characteristic makes it an extremely crucial “adhesive” in the production process of various textile products. China shenghong Double-sided adhesive interlining factory

In terms of process principle, mesh film double-sided adhesive interlining utilizes the property of hot melt adhesives to change state at different temperatures. When a specific heating temperature is reached, the hot melt adhesive component in the mesh film begins to melt, and the liquid hot melt adhesive is able to uniformly penetrate between the fabric fibers, and when it cools and cures, a strong and long-lasting bonding effect is formed. This process has significant advantages over conventional sewing. Traditional sewing requires a lot of time and manpower for stitching, which is not only inefficient, but also may affect the overall aesthetics and texture of the fabric, and in the pursuit of seamless, flat design, traditional sewing is even more difficult to meet the demand. Mesh film double-sided adhesive interlining process can easily realize seamless lamination, greatly improving the production efficiency, while making the product surface more flat and smooth, greatly improving the appearance of clothing, home textile products quality. Double-sided adhesive interlining manufacturers in China

In practical applications, the mesh film double-sided adhesive backing process has been widely penetrated. In the manufacture of clothing, collar, cuffs, lapels, hem and other parts of the fit, embroidered badges fixed, etc., can see its figure. Its application allows the garment to maintain aesthetics while enhancing the firmness of the garment parts and improving the overall quality of the garment. Home textile products, the production of pillows, tablecloths, curtains, etc., the process also plays an important role. For example, the production of pillows, through the mesh film double-sided adhesive backing process will be different colors, materials, fabrics spliced together, not only easy to operate, and the adhesive effect is excellent, can effectively prevent the deformation of the fabrics, while maintaining the original breathability and softness of the fabrics, adding more refinement and comfort for the home life.

It is worth mentioning that the mesh film double-sided adhesive backing process also has outstanding performance in environmental protection. Most of the hot melt adhesive materials used in line with environmental standards, does not contain formaldehyde and other harmful substances, which not only responds to the current consumer pursuit of green products, but also for the textile enterprises to deal with the increasingly stringent environmental regulations to provide strong support.

With the continuous progress of science and technology, mesh film double-sided adhesive interlining process is also continuing to upgrade. On the one hand, manufacturers continue to develop new hot melt adhesive formulations to further enhance the bonding strength of the mesh film, washing resistance and adapt to the bonding needs of more different materials; on the other hand, the heating equipment and process control is also constantly optimized, and strive to achieve more accurate temperature control, to ensure that in the large-scale production, the adhesive effect of each place can reach the best state. China Double-sided adhesive interlining source manufacturers

Mesh film double-sided adhesive backing process is with its unique advantages and continuous innovation of the development trend, become a force to be reckoned with in the textile industry, for the production of textile products to bring more possibilities to promote the whole industry towards more efficient, more environmentally friendly, higher quality direction.