Influence of bonding mechanism and temperature on bonding quality.

First, the function and use of bonding

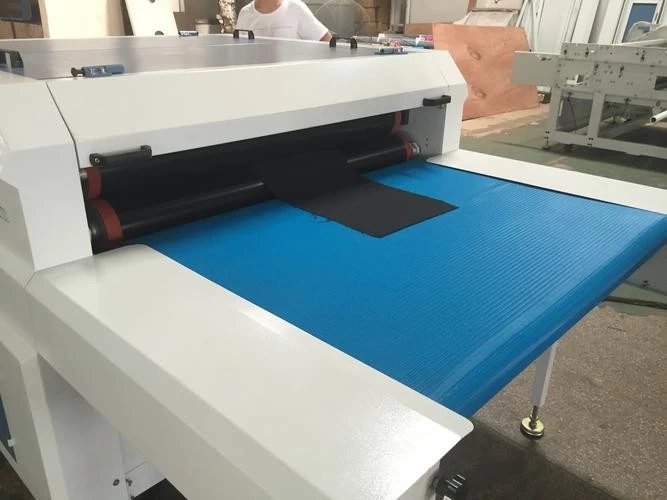

hot melt bonded interlining fabric used adhesive, is a polymer compound adhesive resin (olefin, polyphthalamide, polyurethane and polyester, etc.). Adhesion is attached to the viscous resin fabric or non-fabric, through the control of temperature, time (or speed) and pressure, so that it is bonded to the fabric occurs a new process. Its main properties: thermoplastic; melt state with a certain viscosity; a certain degree of resistance to washing, dry cleaning and aging resistance. The first two properties are the basic conditions for the adhesive to bond with the fabric. Through the process can make the appearance of clothing straight, the shape of the United States, through the bonding process of clothing resistant to dry cleaning, wet cleaning, washing after the whole not wrinkled, not deformed. Therefore, the bonding process is an effective way to improve the quality of clothing and beautify the style. In order to meet the needs of a variety of bonded interlining, bonding machine on the temperature, time (speed), pressure has enough adjustment range, but how to choose the best value of the three parameters, is the effective use of bonding machine, to ensure the quality of clothing key. If the temperature is too high, it is easy to cause deterioration of clothing, heat shrinkage, adhesive aging, brittle after bonding: but the temperature is too low, can not reach the bonding strength, low efficiency. Pressure is too large, the adhesive soak through the fabric, destroying the feel and affect the quality; pressure is too small, affecting the bonding strength; time or speed is not selected properly, but also easy to cause adverse consequences. Due to the parameters with a variety of programs, a variety of bonded lining, and different requirements, so it is necessary to test or practice to be preferred. Commonly used bonding appliances and machines are irons, flatbed bonding machine, rotary continuous bonding machine, high-frequency bonding machine, vacuum bonding machine, electrostatic bonding machine. These devices are suitable for a variety of mass production and specific use requirements.China shenghong interlining suppliers

Second, the bonding conditions

fabrics and adhesive lining bonding, in the selected time and pressure, the temperature is too low is not enough bonding, the product's wash resistance is reduced; if the temperature is too high is over-bonded, the product shrinkage rate rises markedly, and sometimes the bonding strength will be reduced at the same time.Guangzhou non-woven interlining factory

When bonding correctly, the adhesive spreads and penetrates well on the fabric and the bonded interlining; incomplete bonding, due to insufficient penetration of the adhesive, the adhesive does not adhere well to the fabric: and excessive bonding due to too high a temperature, pressure, or time so that the adhesive penetrates through the base fabric or seeps through the fabric. The temperature of the heating plate during bonding should not be too high compared to the maximum temperature of the bonded layer, otherwise it damages the fabric. The temperature of the heating area should be uniform, different temperature will make the fabric parts of the bonding degree is not consistent and the occurrence of wrinkles, seepage of glue, hardening and other phenomena.China shenghong garment lining manufacturer