How to match fusible interlining cloth and fabric correctly?

(A) Cotton material

Cotton fiber is favored for its good moisture absorption, moisture retention, heat resistance, alkali resistance and hygienic properties. Its high heat resistance makes it relatively stable when bonded during the pressing process with good recovery after pressing. However, it should be noted that the shrinkage of cotton fabrics is more prominent, in the choice of fusible interlining, be sure to ensure that the shrinkage of cotton and interlining is consistent, in order to avoid deformation of the garment after washing.China garment accessories factory

(B) hemp fabric

Fabrics made of hemp fiber have a unique texture, but there are certain challenges when working with fusible interlining. Since hemp is not easy to obtain bonding strength, reasonable pressing conditions need to be precisely determined to obtain good bonding results. During the production process, parameters such as pressing temperature, time and pressure need to be carefully adjusted to achieve a strong bond between the hemp fabric and the fusible interlining.

(C) silk thick

Silk belongs to heat-sensitive fibers, and its surface is extremely easy to get aurora when pressurized and heated, which seriously affects the appearance of the fabric. Therefore, when choosing fusible interlining for silk fabrics, we should avoid using high temperature and high pressure, and should use low temperature fusible interlining. In the processing of the need to strictly control the temperature, with the appropriate low-temperature fusible interlining, in order to maintain the elegant luster and texture of silk fabrics. Silk and other smooth surface fabrics, bonding is more difficult. For this type of fabric, it is appropriate to choose fine (high) mesh coating fusible interlining. China shenghong low-temperature fusible interlining manufacturer

(D) tweed wool

Wool fibers and humidity (moisture content) is closely related to the size of the moisture absorption increases, and vice versa. In the choice of fusible interlining, to give full consideration to the interlining and fabric size of the synchronous changes, as well as bonding the degree of moisture content of the front material wool fibers.

(E) synthetic fabrics

Combined fiber fabrics are usually high temperature shaping treatment to ensure dimensional stability. When bonding and pressing, the temperature must be lower than the heat setting temperature, otherwise it will destroy the setting effect. In addition, the new synthetic fiber has a fine, soft, crease recovery and other characteristics, which requires the interlining fabric with soft, straight and not easy to shrink, anti-twisting and bonding properties.

Composite fiber performance is more complex, which requires the interlining fabric has a good with the movement, stretch, can be sewn, softness, drape and comfort!

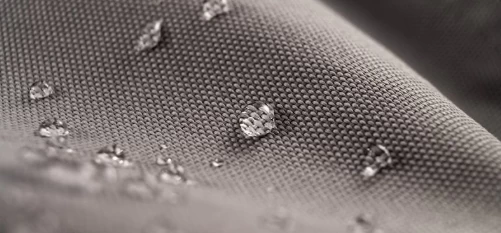

(F) elastic fabrics

Elastic knitted fabrics with its four-way elasticity as a significant feature. In the lining for such fabrics, the key to choose and fabrics with the same elasticity and stretch properties of the adhesive lining to ensure that the garment is not deformed in the wearing process. China shenghong Elastic interlining factory

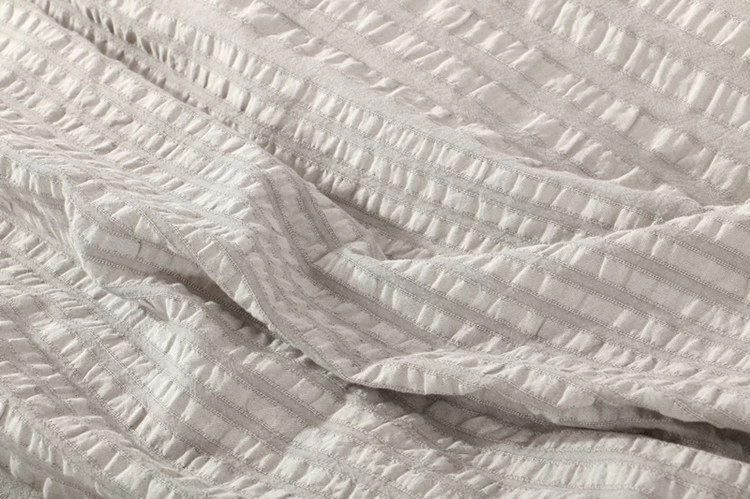

(G) special style fabrics

Bubble yarn, face crepe, flannel and other surface style of special fabrics, in order to avoid the destruction of its unique style due to bonding pressure ironing, should choose low-pressure bonding conditions. The surface of the silicone oil or resin finishing fabrics, due to its bonding difficulty, need to choose high-pressure bonding conditions.