How do interlining fabrics achieve anti-static function? The original has these five points

1. Anti-static fiber

A common method is to use antistatic fibers. These fibers have a high degree of hygroscopicity and can adsorb water molecules in the air, thus improving the conductivity of the fiber and reducing the generation of static electricity. For example, polypropylene fibers, polyethylene fibers and viscose fibers are common antistatic fibers. Newer antistatic fibers, such as lisle fibers and nylon 11 fibers, have poor adsorption of electrical charges and therefore have long-lasting antistatic properties. However, garments made of these new antistatic fibers are relatively expensive.Anti-static Interlining supplier

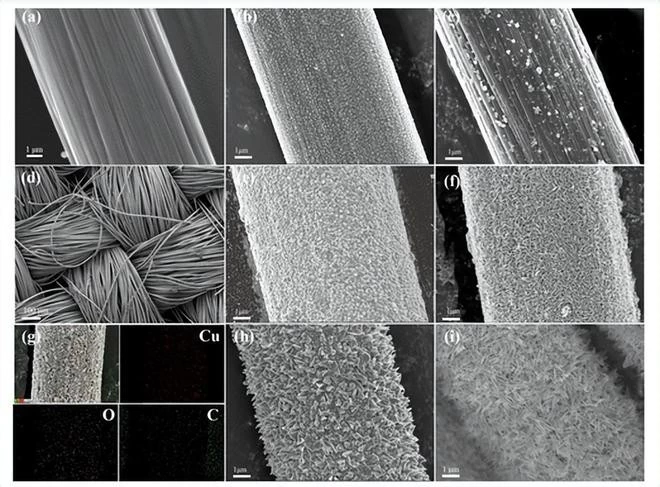

2. Blended or embedded conductive fibers

Another effective method is to blend or embed conductive fibers in the interlining. Conductive fibers, such as metal fibers, conductive polymer fibers, etc., has excellent conductive properties, can effectively reduce the surface resistivity of the fiber, thus giving the textile antistatic properties. When the static voltage on the clothing reaches a certain value, the conductive fibers will produce a non-sparking corona discharge between the natural elimination of static electricity. This method is not only long-lasting anti-static, but also applicable to the production of a wide range of textiles.

3.Coating Finishing

Surface coating finishing is also an important means of realizing the antistatic function of interlining fabrics. Through the use of composite conductive materials for coating finishing, can form a layer of conductive layer on the surface of the fabric, improve the conductivity of the fiber, reduce the surface resistivity, thereby reducing the accumulation of static electricity. Although this method is low-cost and simple to operate, it may affect the breathability and feel of the fabric, and therefore is not applicable to intimate apparel and home textiles.china shenghong interlining manufacturer

4. Antistatic finishing agent

The use of antistatic finishes is another common treatment. Antistatic finishes can effectively direct and eliminate the build-up of static charges by forming a conductive layer of insoluble polymers on the surface of the fabric. These finishes are often compatible with other additives such as water repellents and softeners and can be used in the same bath to shorten processing steps and reduce processing costs. For example, Texnology® NW16 Antistatic Finish is a non-ionic antistatic finish that forms a conductive layer on the surface of fabrics, effectively reducing static buildup.

5. Ground connection and humidity control

In certain applications where special anti-static properties are required, such as anti-static garments, ground connections can also be used to direct static charges to the ground, thereby reducing the rate and amount of charge buildup. In addition, maintaining the proper humidity of the environment can also effectively reduce the generation of static electricity. Humidity control is a non-negligible part of the anti-static treatment of textiles.,shenghong interlining factory china