Differences between knitted and woven interlinings

1. Differences in production process

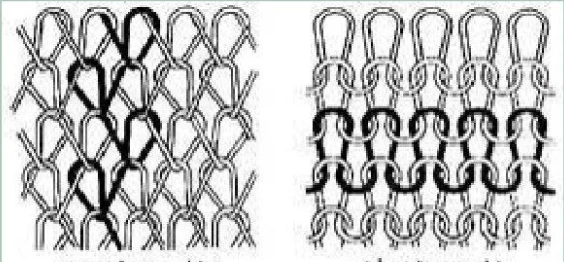

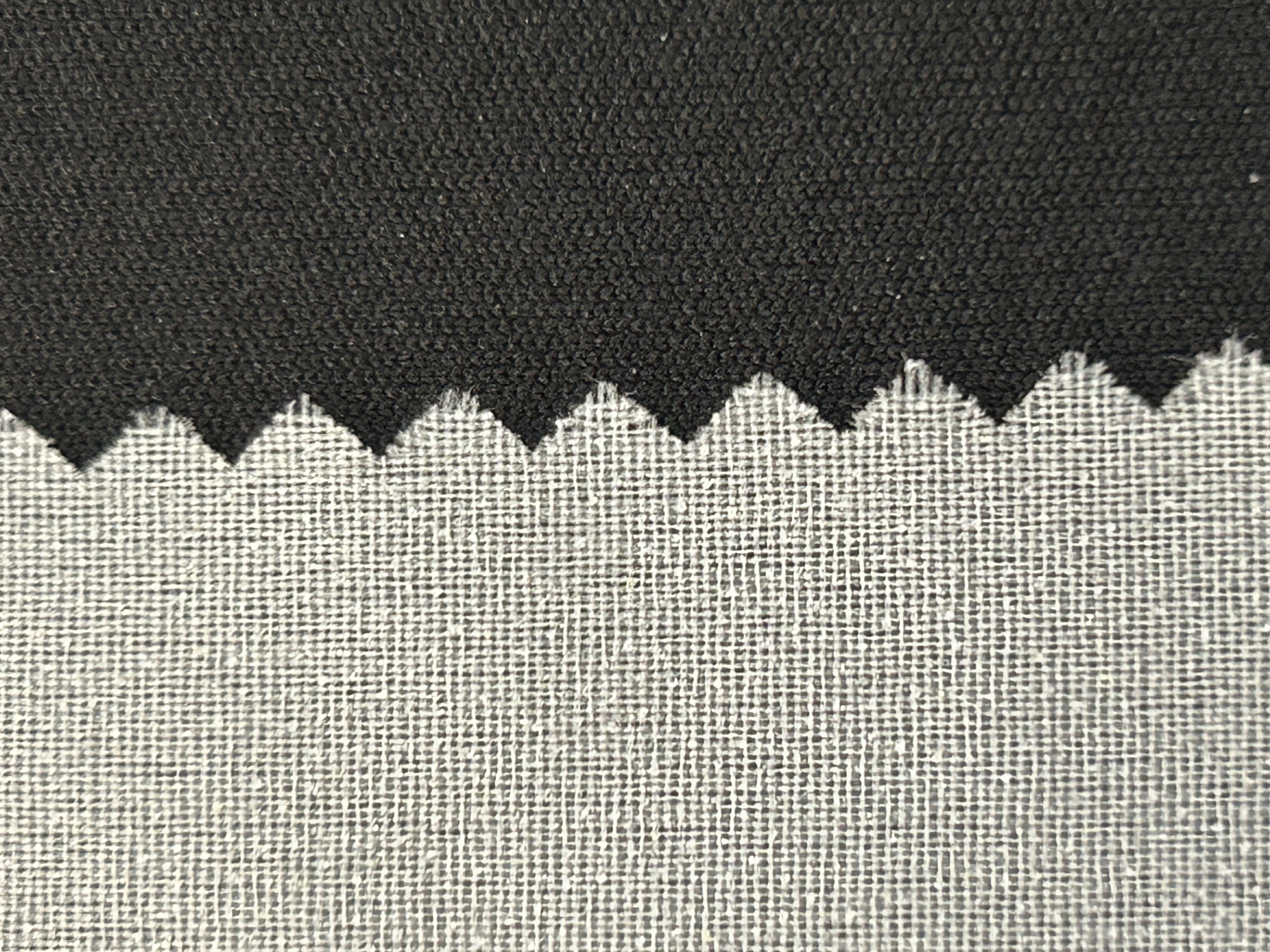

Knitted interlining is made by stringing yarns to each other according to a certain pattern through a knitting machine. This kind of knitting makes the knitted interlining fabric has a unique coil structure, so its elasticity is excellent, can adapt to the body's curve changes, comfortable to wear. At the same time, the production process of knitted interlining is relatively simple, high production efficiency and relatively low cost.

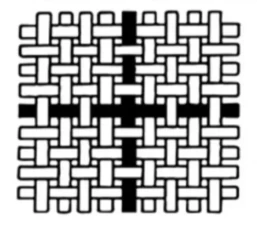

Woven interlining, on the other hand, is made by shuttles driving the weft yarns to weave between the warp yarns. This weaving method makes the structure of woven interlining more stable, and the warp and weft yarns are closely interwoven, so it has high strength, good abrasion resistance, and good shape retention. However, the production process of woven interlining is relatively complex, low production efficiency, relatively high cost.

2. The difference in performance characteristics

Knitted interlining fabric:

(1)Good elasticity: the coil structure of knitted interlining fabric gives it good elasticity, which can adapt to various curves of the body and make it more comfortable to wear.

(2)Good breathability: the gaps between the coils make the knitted interlining fabric have good breathability, even in hot weather can remain comfortable.

(3)Moisture wicking: Knitted interlining is usually made from natural fibers such as cotton and wool, so it has good moisture wicking properties to keep the body dry.

Woven Interlining:

(1)Structural stability: the warp and weft yarns of woven interlining are closely interwoven, which makes its structure more stable and not easy to deform.

(2)Good abrasion resistance: Due to the interweaving of the warp and weft yarns, woven interlining has good abrasion resistance, which is suitable for the production of clothing parts that require frequent friction.

(3)Good shape retention: woven interlining can maintain a good shape, suitable for the production of clothing that requires a firm shape.

3. The difference in application areas

Knitted interlining fabrics are usually used to make casual wear, sportswear, underwear and other garments that need to fit the body's curves because of their good elasticity and breathability. In addition, knitted interlining fabric is also commonly used in the production of hats, scarves and other accessories.

Woven interlining fabrics, on the other hand, are usually used for formal wear, suits, shirts, and other garments that need to maintain a straight shape because of their stable structure, good abrasion resistance, and good shape retention. Woven interlining is also commonly used for curtains, bedding and other home furnishings.China non-woven interlining suppliers