Adhesive Film Interlining: The Functional Mystery and Multiple Applications of Textile Accessories

Adhesive film interlining, also known as fusible interlining or hot melt interlining, is a kind of textile accessory that is bonded to fabrics by hot pressing. It consists of a base fabric and a hot melt adhesive coating, and is widely used in the fields of garments, bags and household products. The main function of film interlining is to enhance the stiffness, stability and durability of fabrics, and at the same time improve the molding effect and wearing comfort of garments.China shenghong Adhesive Film Interlining manufacturer

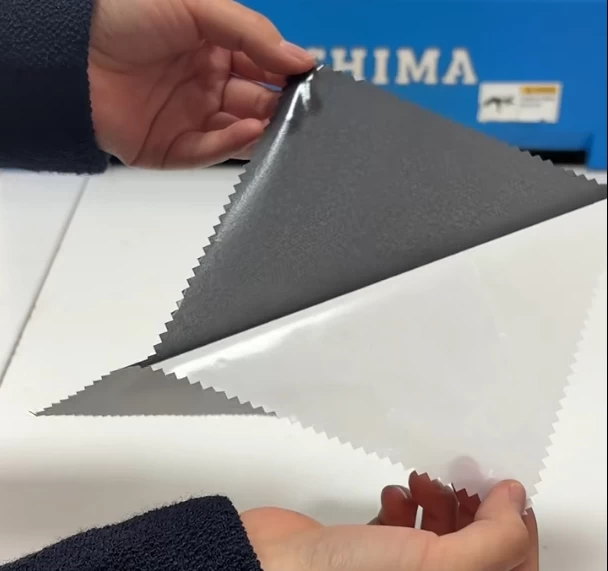

The structure of adhesive film interlining mainly consists of a base fabric layer and a hot melt adhesive layer. The base layer is made of a variety of materials, including cotton, polyester/cotton blends, pure polyester and non-woven fabrics, etc. The weaving methods are organic fabrics, knitted fabrics and non-woven fabrics, and the weight specifications range from 15g/m² to 150g/m². The main components of the hot melt adhesive layer are PA, PE, PES and EVA, etc. The coating methods include powder dot coating, paste dot coating, powder coating and double dot coating.

There are various types of adhesive film lining, which can be divided into woven lining, knitted lining and non-woven lining according to the material of base cloth. Woven interlining has good stability and is suitable for high-grade suits and coats; knitted interlining has good elasticity and is suitable for elastic fabrics; non-woven interlining has low cost and is mostly used for low- and medium-grade garments. According to the type of hot melt adhesive can be divided into PA adhesive interlining, PES adhesive interlining, PE adhesive interlining and EVA adhesive interlining; PA adhesive interlining strong adhesive strength, dry cleaning resistance, used for high-grade clothing; PES adhesive interlining resistant to washing, suitable for frequent washing of clothing; PE adhesive interlining low price, used for low-end products; EVA adhesive interlining low-temperature adhesion, suitable for heat-sensitive fabrics. According to the use can be divided into clothing lining, shoes and hats lining, luggage lining and home lining and so on.China Adhesive Film Interlining suppliers

The core performance indexes of adhesive film interlining include bonding strength, washing resistance, heat shrinkage, hand-feeling performance, air permeability and resilience. Adhesive strength determines the degree of firmness of the combination of interlining fabrics and fabrics; washing resistance, including washing resistance and dry cleaning resistance; thermal shrinkage affects the dimensional stability at high temperatures; feel performance determines the impact of interlining fabrics on the feel of the original fabric; breathability affects the comfort of wearing; rebound has an important impact on the conformability of the garment.

The application process of adhesive film interlining mainly includes the bonding process and solutions to common problems. The key points of the bonding process include temperature control, pressure control, time control and cooling and molding. Common problems include poor bonding, glue penetration, blistering and deformation, etc., which can be solved by adjusting the temperature, pressure, glue matching and cooling.

The following principles should be followed when selecting film interlining: matching with fabrics (considering composition, thickness, color, etc.), matching with garment parts (different requirements for different parts), matching with washing methods (selecting adhesive according to the washing requirements), matching with processing conditions (considering the conditions of the factory equipment), and the principle of economy (controlling the cost under the satisfaction of the requirements).

The development trend of adhesive film liner includes environmentally friendly liner (biodegradable base cloth, environmentally friendly adhesive), functional liner (anti-bacteria, anti-static, breathable, etc.), intelligent liner (temperature-sensitive, shape-memory, etc.), thin high-strength liner (thinner and lighter with good performance), and customized liner (personalized solutions).

When storing film interlining fabrics, it should be noted that: stored in a cool and dry place, avoid direct sunlight; relative humidity control below 65%; flat to avoid adhesion of the adhesive layer; the shelf life is usually 1-2 years, the expiration date needs to be re-tested performance.

As an important auxiliary material in modern garment industry, the performance of adhesive film interlining directly affects the quality of the final product. With the development of material science and textile technology, adhesive film interlining is progressing towards more environmentally friendly, smarter and higher performance.shenghong interlining factory China